Detailed Report On Iron Foundry

An Iron Foundry is a place where iron is melted, shaped, and cast into various objects. It is a facility where molten iron is poured into molds to create a wide range of products.

What is Iron Foundry?

Detailed Report on Iron Foundry is as Follows:

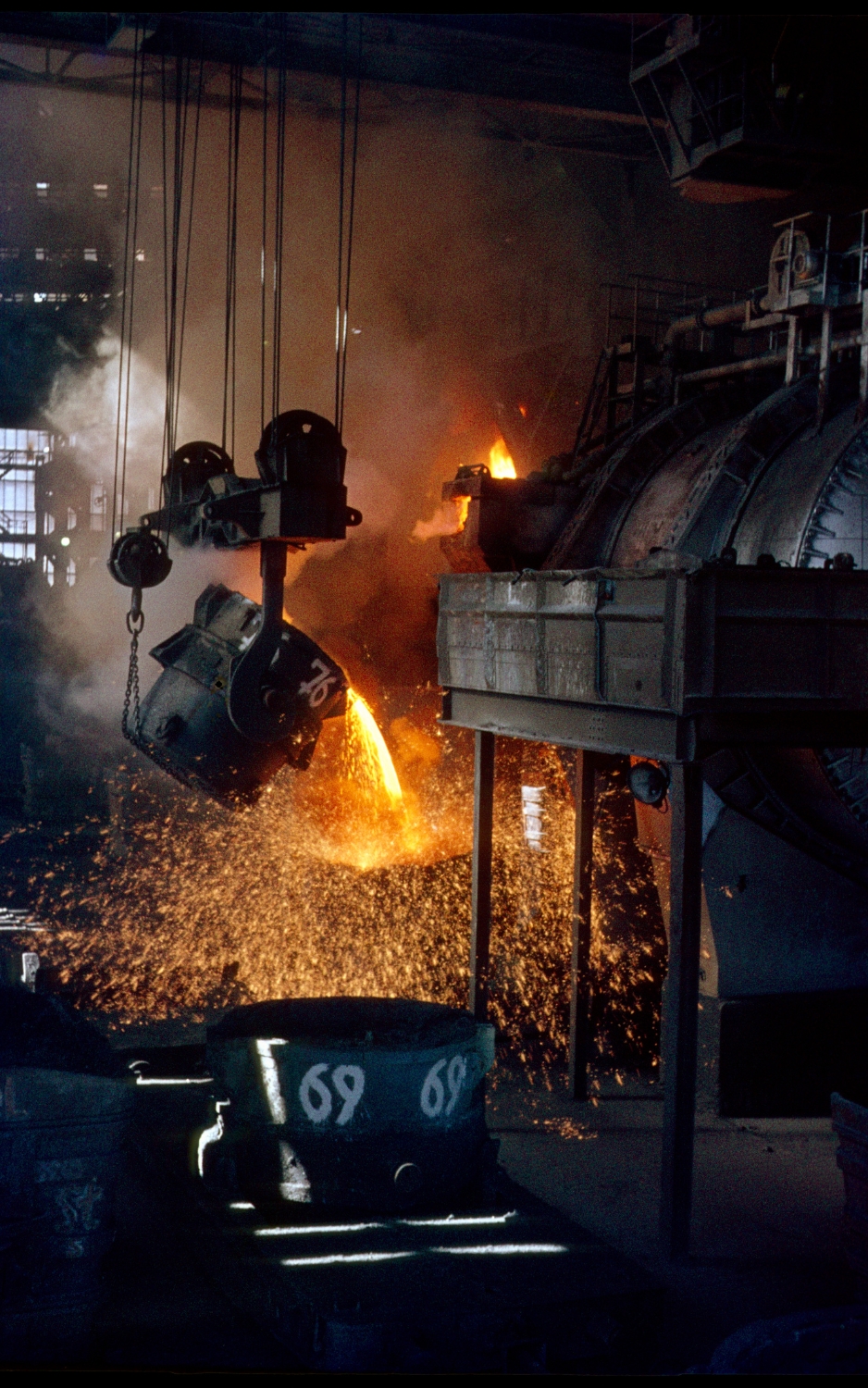

A Iron foundry is a metal casting manufacturing plant. Metals are cast into shapes by melting them into a liquid, pouring the metal into a mold, and then removing the mold material when the metal cools. Aluminum and cast iron are the two most often treated metals. Bronze, brass, steel, magnesium, and zinc are some of the other metals utilized in foundries to manufacture castings. To fully understand a foundry, one must first understand the casting process. The general steps in casting are patternmaking, molding, melting, pouring, ejection, cleaning, fettling, and inspection.

Parts of various forms and sizes can be created during this operation. Foundries contribute considerably to the manufacturing recycling movement by melting and recasting millions of tonnes of waste metal each year to create new long-lasting commodities. Furthermore, sand is employed in the molding process by several foundries. Sand is another type of recycling that these foundries regularly use, recondition, and reuse.

Molds are meticulously molded with a pattern – a wood or metal replica of the thing to be cast – because the final casting shape coincides with the mold it is poured into. The most common mold material is silica sand, however, depending on the casting metal and process used, they can be manufactured from a number of materials. A melting furnace is “charged” with metal and heated to temperatures exceeding the metal’s melting point. When the molten metal reaches a certain pouring temperature, it is tapped from the furnace into a refractory walled steel pouring ladle via a spout. The molten metal’s surface is cleaned of slag and impurities. The ladle is then twisted so that molten metal flows into the cavity of the mold.

Detailed Report Sample On Iron Foundry

Market Potential Of Iron Foundry

The Global Iron Casting Market is expected to be worth USD 15.13 billion by 2030, growing at a 5.8% CAGR between 2023 and 2030.

The global iron casting market has grown dramatically in recent years, owing to increased demand from industries as diverse as automotive, construction, and industrial machinery. Iron-casting goods are in high demand due to their high strength, durability, and cost-effectiveness. Grey cast iron is expected to account for more than 64% of total sales in the Iron Casting Market. Grey cast iron is a low-cost alternative to other iron and metal alloys, making it a popular choice for a variety of applications.

Cast iron is widely employed in the automotive industry, where it is used to make engine blocks, cylinder heads, and brake systems, among other things. The global automobile industry has grown dramatically in recent years as a result of rising disposable income, a growing population, and urbanisation. This growth is expected to continue, driving up demand for iron castings in the automobile industry.

Contents of Project Report

A project report helps you identify whether a project is worth pursuing. It presents the holistic view and brings complete insight of the business and its activity.

It acts as a guide for all the business operations, aids in taking all financial decisions related to the existing businesses and to the start-ups. It serves as roadmap to the business and provides information to the outsider who are wanting to know more about the business.

You will have the opportunity to build new goals and expansion ideas in one single document. Everyone, from the banks to potential investors, will need to have a look at the project report before they shell out any money.

A well drafted project report generally consists details about:

- Brief History of the Business

- The Promoters

- SWOT Analysis

- Industry Outlook

- Past Financial Statements

- Projected Financial Statements

- Infrastructure and Human Resource required

- CMA data

- Business model

- Requirement of Working Capital Funds

- Means of Finance

Other relevant information, if any.