Detailed Report On Electronics Product Manufacturing

Electronics product manufacturing encompasses the creation of devices like smartphones, laptops, and gadgets. It involves design, assembly, and quality control to produce advanced technology that impacts daily life and various industries.

Introduction

Detailed Report on Electronics Product Manufacturing is as follows.

The production of electronic products is a complex and dynamic process that involves the fabrication of numerous electronic devices and components. It encompasses a wide variety of activities, from design and prototype through mass manufacturing and quality assurance. This business is vital to contemporary living, generating essential items such as cellphones, laptop computers, appliances, medical equipment, and more. The industry’s evolution is fuelled by technological breakthroughs, environmental concerns, and market dynamics, and it has become a foundation of the global economy.

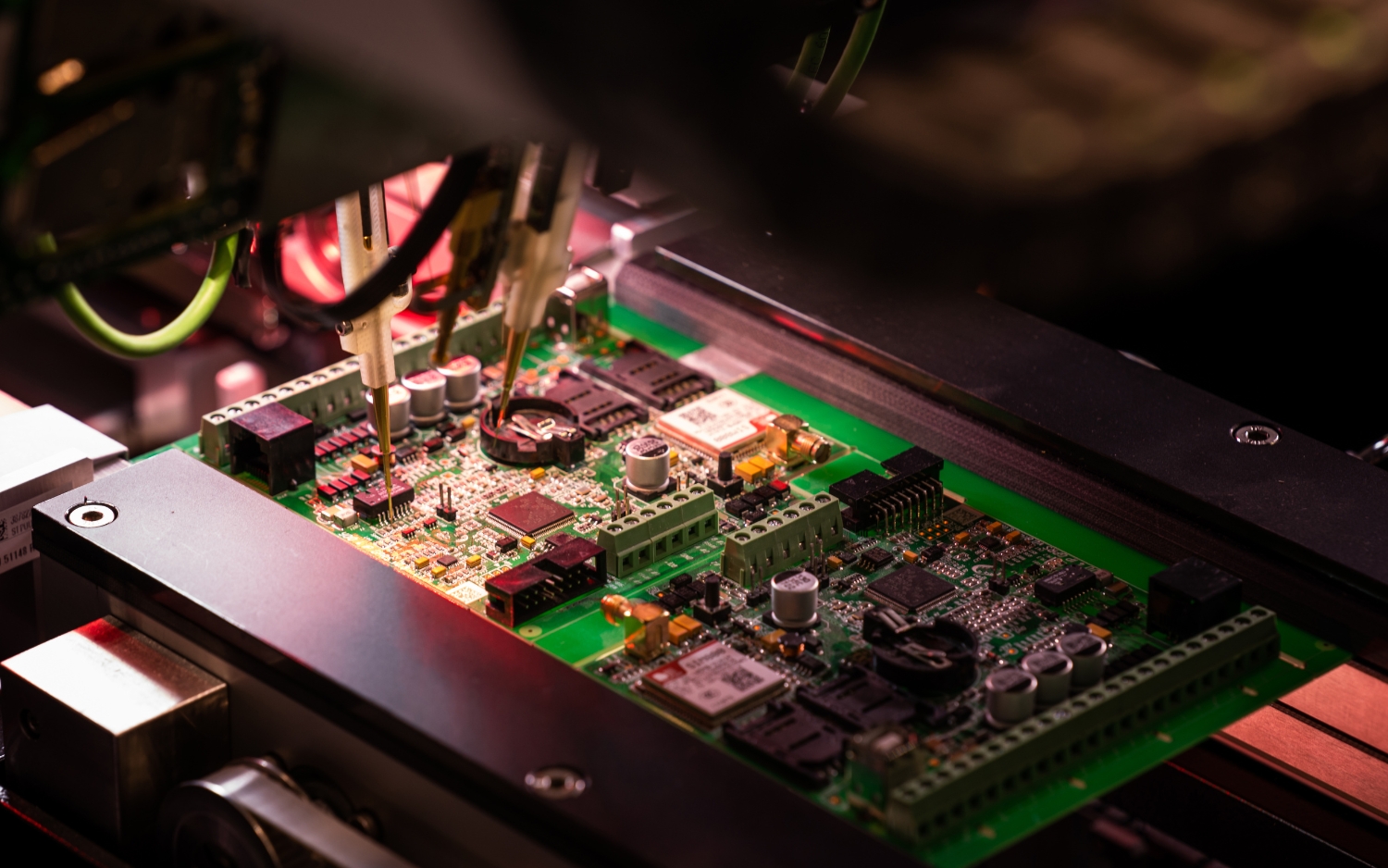

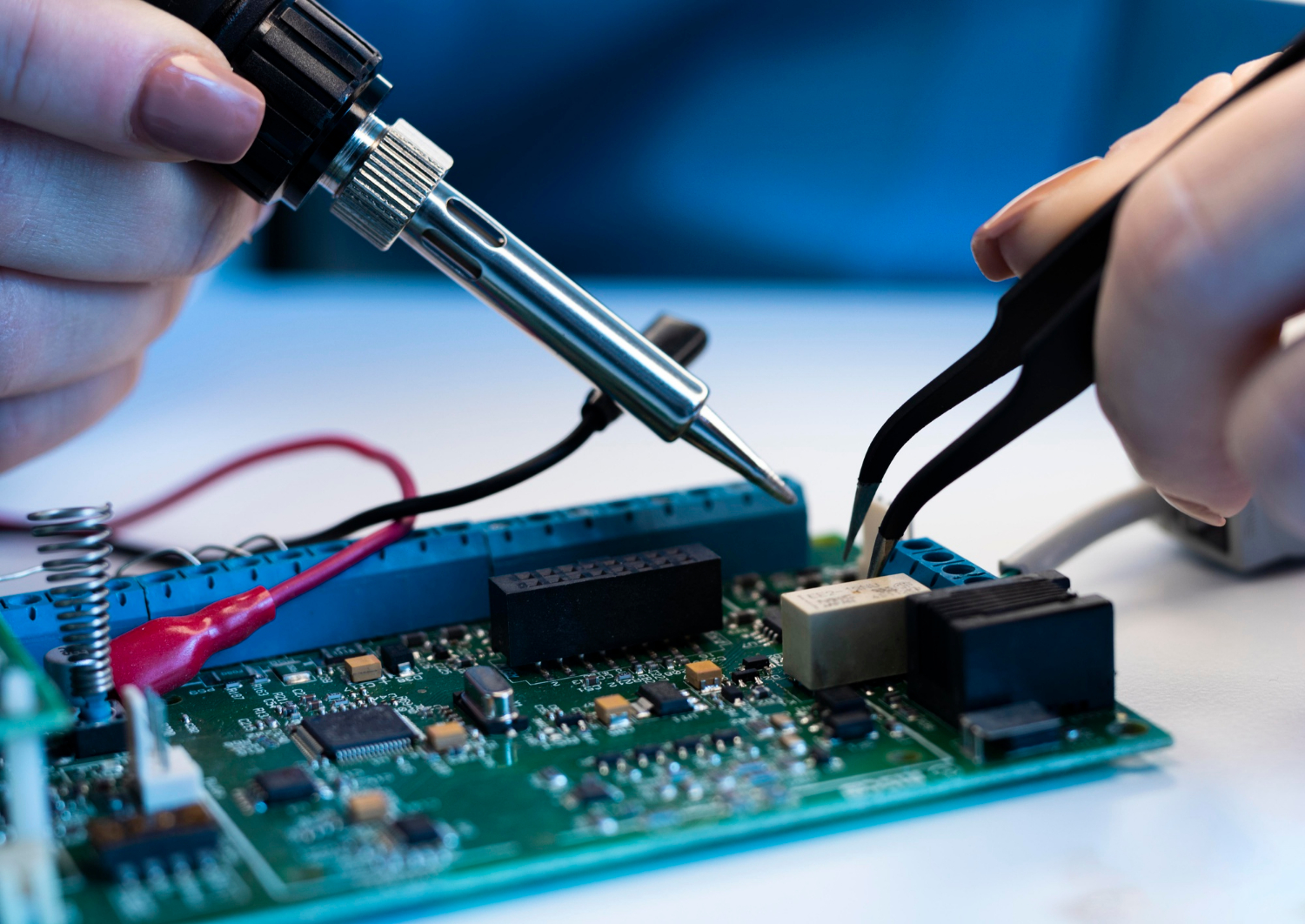

Product design and engineering specialists conceptualize the electronic item’s functionality, aesthetics, and technical specifications. Prototypes are developed after the design has been approved to test and refine the product’s performance and usefulness. This repeated technique ensures that the final result meets the specified specifications. The manufacturing process then begins, which entails the manufacture of components and their assembly into the completed product. This typically entails purchasing raw materials like as semiconductors, resistors, capacitors, and polymers. Advanced manufacturing techniques like as surface-mount technology (SMT) and automated assembly lines are utilized to fast and correctly create complicated electronic circuits.

Quality assurance is a critical component of the electronics manufacturing process. Rigid testing and inspection procedures are used at various stages to expose flaws and ensure the product’s reliability, safety, and conformity with industry standards. This includes functional testing, environmental stress testing, and durability testing. Sustainability and environmental issues are becoming more important as the demand for electronics develops. Manufacturers are implementing environmentally friendly practices such as reducing energy use, reducing waste, and establishing recycling operations. The electronics product manufacturing business is characterized by rapid technical breakthroughs. Material, miniaturization, automation, and connection innovations allow for continuous improvements in product performance and design. Furthermore, global supplier chains, trade rules, and market changes all influence manufacturing processes and prices.

Detailed Report Sample On Electronics Product Manufacturing

Market Potential Of Electronics Product Manufacturing

In 2023, the worldwide electronic manufacturing services market is expected to be valued US$ 541554.4 million. Sales and demand for consumer gadgets are driving growth. Between 2023 and 2033, global demand for electronic manufacturing services is predicted to grow at a CAGR of 4.7%, reaching about US$ 859959.3 million.

The worldwide electronics manufacturing services (EMS) market is classified into the following categories: computer, consumer electronics, aerospace & military, medical & healthcare, automotive, semiconductor manufacturing, robotics, and other applications. Rising functionality, such as engineering, component assembly, and design of premium circuit boards, contract manufacturing functional testing, and sub-assembly production, are driving drivers in the worldwide market for electric manufacturing services.

Electronic Manufacturing Services suppliers boost flexibility by reacting to unanticipated demands quickly and effectively. Electronics Manufacturing Services, Engineering Services, Test & Development Implementation, Logistic Services, and Others comprise the Global Electronics Manufacturing Services (EMS) Market.

Furthermore, electronic contract manufacturing techniques provide engineering and manufacturing outsourcing services with a broad variety of core production competences. Furthermore, outsourcing auxiliary roles helps OEMs to focus on their core expertise, improving operational performance, lowering manufacturing costs, and requiring less fixed capital investment. The electronic goods market consists of electronic product sales by enterprises that produce electronic products (organizations, single proprietorships, and partnerships).

Contents of Project Report

A project report helps you identify whether a project is worth pursuing. It presents the holistic view and brings complete insight of the business and its activity.

It acts as a guide for all the business operations, aids in taking all financial decisions related to the existing businesses and to the start-ups. It serves as roadmap to the business and provides information to the outsider who are wanting to know more about the business.

You will have the opportunity to build new goals and expansion ideas in one single document. Everyone, from the banks to potential investors, will need to have a look at the project report before they shell out any money.

A well drafted project report generally consists details about:

- Brief History of the Business

- The Promoters

- SWOT Analysis

- Industry Outlook

- Past Financial Statements

- Projected Financial Statements

- Infrastructure and Human Resource required

- CMA data

- Business model

- Requirement of Working Capital Funds

- Means of Finance

Other relevant information, if any.