Detailed Report On Fabrication Unit

Metal structures are produced by a fabrication unit using bending, cutting, and assembly techniques. It provides precision, quality, and customization to a range of sectors. The production of components for the building, automotive, aerospace, and other industries depends heavily on this facility.

Contact Us

What is Fabrication Unit?

Detailed Report on Fabrication Unit is as follows.

The artful process of turning raw materials into finished goods that are both useful and frequently gorgeous is called fabrication. It’s similar to industrial-scale sculpture, utilizing a wide variety of materials, including metals, polymers, wood, and composites, and a variety of techniques to realize ideas and designs.

An innovative center, a fabrication and manufacturing shop is where master craftsmen and state-of-the-art technology come together to realize a variety of ideas. These workshops, which are located in the center of industrial zones, are devoted to the fabrication and assembly of metal structures, machine parts, and specialty components. A careful dance between raw materials—typically steel, aluminum, or other alloys—and a symphony of equipment, such as welding stations, cutting tools, and precise instruments, characterizes the fabrication process.

Fabrication is the process of building items by utilizing one or more separate processes to combine pieces that are usually standard. For instance, steel fabrication is the process of creating metal structures by bending, cutting, and assembling them. Frequently, metal fabrication creates a whole assembly from smaller sub-assemblies that can be used with readily accessible standard pieces. This is made possible by computer-aided designs (CAD), which are frequently programmed using computer numerical control (CNC) technology. CNC technology allows direct communication between the factory floor machinery and its operators.

The grill fences and railings fabrication industry in India comprises various medium and small companies that manufacture wide range of simple and decorative ornamental products form mild steel, stainless steel sections tubes and rods, as also from cast items. The units in this sector compete with offer for various innovative designs and patterns with lowest costs. The medium and small companies are located all over India and also take up the general fabrication services to industries.

Gates, Grills, Fencing are essentially made from steel via fabrication of various sections, sheets and pipes. These products are a norm for all most all premises to install to cover area under their ownership. Railings and grills are part of protection and are also used as structure for most of stairways, people movement management and to provide natural view of both inside or outside of the covered areas.

Detailed Report Sample On Fabrication Unit

Market Potential Of Fabrication Unit

The India Fabrication Works Market size is estimated at USD 20.89 billion in 2023, and is expected to reach USD 28.46 billion by 2028, growing at a CAGR of 6.38% during the forecast period (2023-2028).

Metal fabrication is an integral part of India’s manufacturing sector, contributing significantly to the country’s economic growth. It involves the process of cutting, bending, and assembling various metal components to create a final product. The India metal fabrication market encompasses a wide range of industries, including automotive, construction, aerospace, and energy, among others. The market has witnessed steady growth over the years, driven by factors such as infrastructure development, industrialization, and technological advancements.

The India metal fabrication market has experienced substantial growth in recent years. The market is fuelled by the country’s rapid industrialization, growing infrastructure projects, and increasing demand for fabricated metal products. Key players in the industry are continuously investing in research and development activities to enhance their product offerings and cater to evolving customer requirements. The market is highly competitive, with several domestic and international players vying for market share.

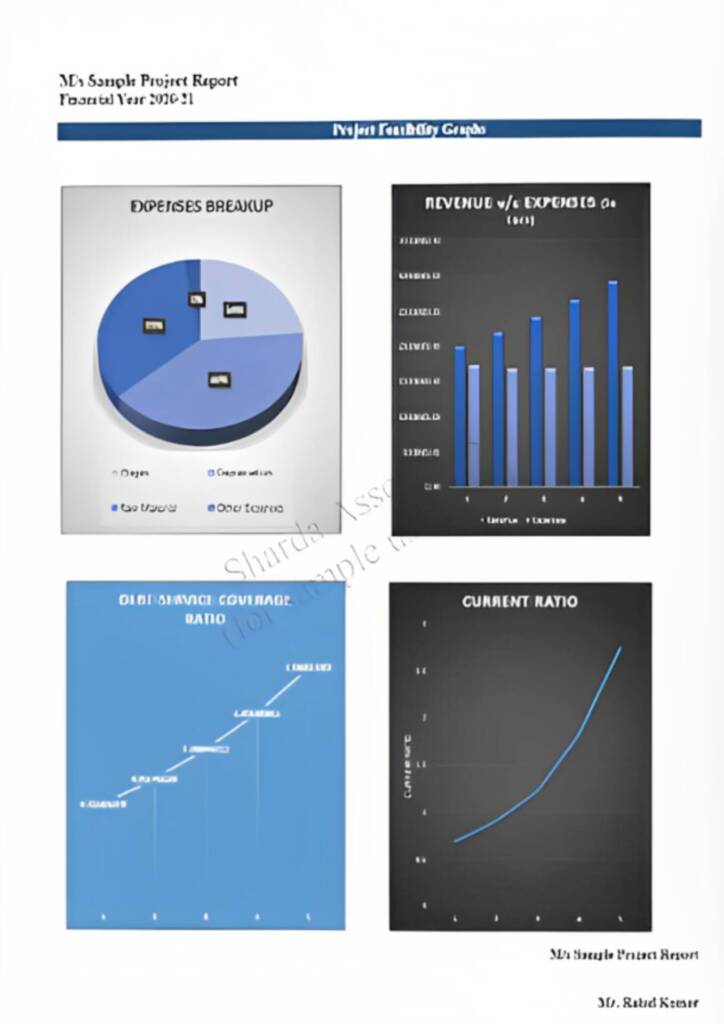

Contents of Project Report

A project report helps you identify whether a project is worth pursuing. It presents the holistic view and brings complete insight of the business and its activity.

It acts as a guide for all the business operations, aids in taking all financial decisions related to the existing businesses and to the start-ups. It serves as roadmap to the business and provides information to the outsider who are wanting to know more about the business.

You will have the opportunity to build new goals and expansion ideas in one single document. Everyone, from the banks to potential investors, will need to have a look at the project report before they shell out any money.

A well drafted project report generally consists details about:

- Brief History of the Business

- The Promoters

- SWOT Analysis

- Industry Outlook

- Past Financial Statements

- Projected Financial Statements

- Infrastructure and Human Resource required

- CMA data

- Business model

- Requirement of Working Capital Funds

- Means of Finance

Other relevant information, if any.