Feasibility Report On Car Manufacturing

Car manufacturing is the process of creating automobiles, involving assembling various components and systems to produce functional vehicles in large-scale production facilities.

Introduction

Feasibility Report For Car Manufacturing.

Car manufacturing is the process of production of large quantities of automobiles. It has several stages, including design, engineering, and manufacturing. Initially, automotive designers create designs and prototypes that take into account aesthetics, functionality, and safety. Following that, engineers will use these designs to create mechanical and electrical systems. Then, manufacturers set up assembly lines where specialized employees create the vehicles, installing engines, chassis, interiors, and external components. Quality control measures ensure that the finished cars meet regulatory standards as well as consumer expectations. Car production combines new technologies, skilled labor, and effective logistics to create vehicles that have transformed transportation and become a vital component of modern society.

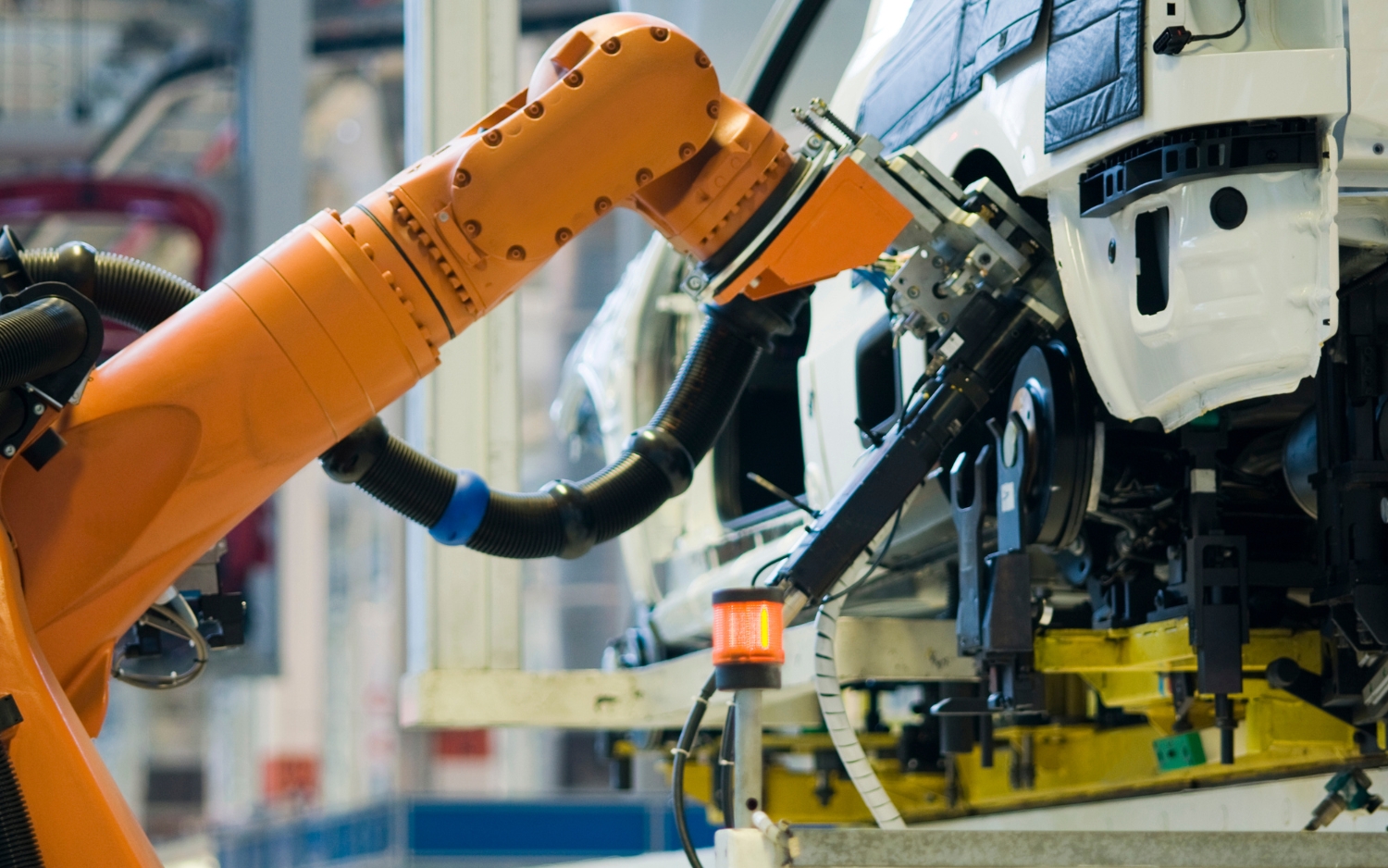

The production phase of automotive manufacturing begins once the design is complete. This stage entails the creation of cutting-edge assembly plants outfitted with highly automated machinery and production lines. Steel, aluminum, polymers, and electronics are sourced and turned into components before being combined to produce the finished product. Quality control and assurance are essential components of automotive manufacture. Stringent testing processes are in place to guarantee that safety, performance, and durability standards are met. Every car is subjected to rigorous testing, from crash tests to environmental studies, before it is released to the public.

Automobile production also includes a large network of suppliers and logistics partners. These institutions work together to ensure that components and materials are delivered to assembly plants on schedule, allowing for more efficient production processes. The industry’s importance goes beyond only production. It creates jobs, promotes technological developments, and contributes to economic prosperity. Automobile manufacturers frequently take an active role in sustainable practices, creating electric and hybrid vehicles to cut carbon emissions and reduce environmental impact.

Feasibility Report Sample On Car Manufacturing

Market Strategy of Car Manufacturing

The Indian passenger automobile market is predicted to grow to US$ 54.84 billion by 2027, with a CAGR of more than 9% between 2022 and 2027.

By 2025, India’s electric vehicle (EV) industry is expected to reach Rs. 50,000 crore (US$ 7.09 billion). This will demand an expenditure of approximately US$ 180 billion in vehicle manufacture and charging infrastructure. A lot of factors influence the automobile business, including the availability of low-cost skilled labor, powerful R&D centers, and low-cost steel production. The industry also offers excellent investment prospects as well as direct and indirect employment to skilled and unskilled labor. The electric car sector is expected to generate five crore