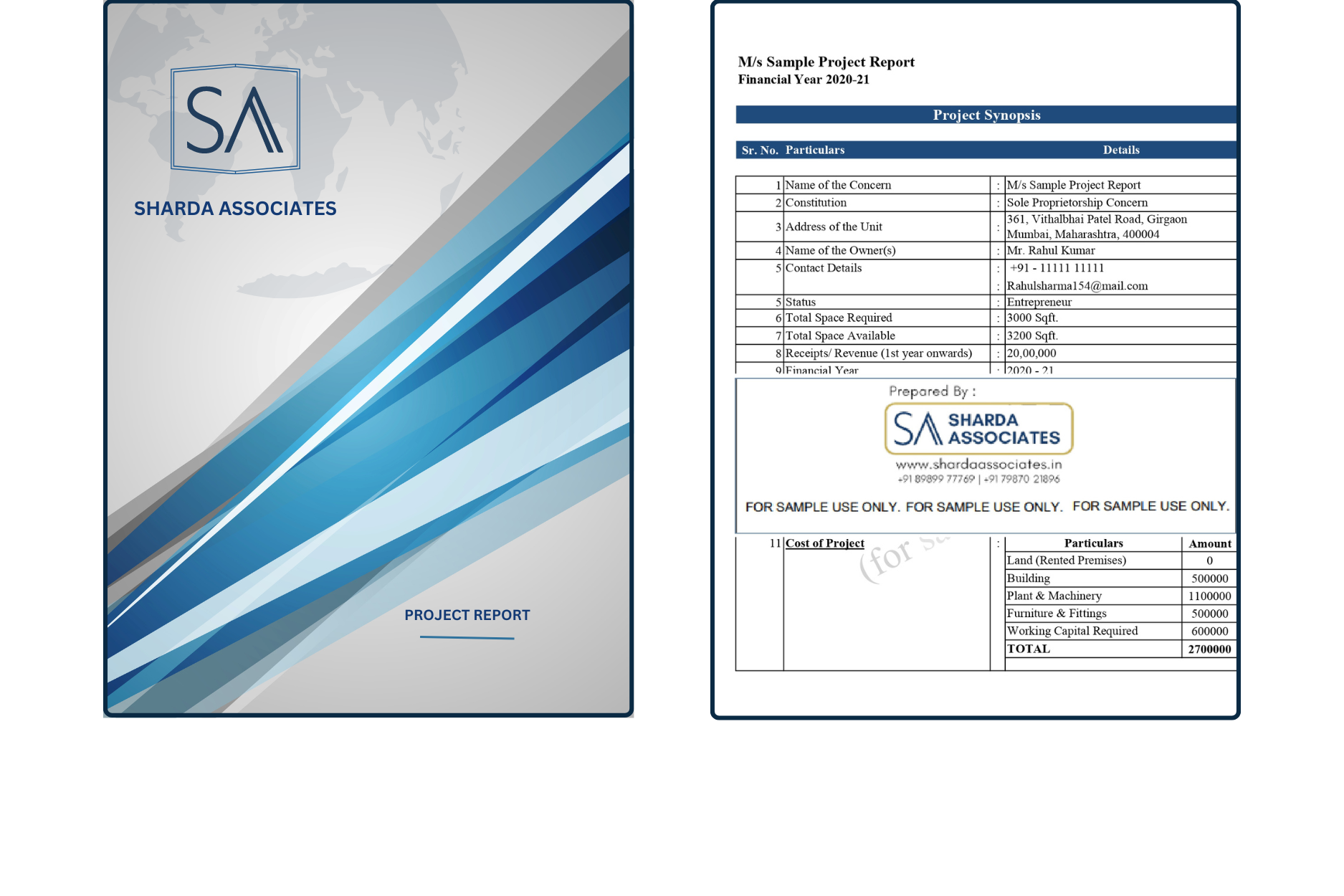

Feasibility Report On Fabrication Unit

The fabrication unit uses assembly, bending, and cutting procedures to create metal structures. Many industries can benefit from its accuracy, excellence, and customization. This plant plays a major role in the manufacturing of components for the construction, automotive, aerospace, and other sectors.

Introduction

Feasibility Report For Fabrication Unit.

Fabrication is the creative process of transforming raw materials into final products that are often beautiful and functional. It is comparable to industrial-scale sculpture in that concepts and designs are realized using a diverse range of materials and processes, such as metals, polymers, wood, and composites.

Modern technology and skilled artisans combine in an inventive fabrication and manufacturing shop to achieve a range of concepts. These workshops are specialized to the manufacture and assembly of metal structures, machine parts, and specialty components. They are situated in the heart of industrial zones. The fabrication process is characterized by a meticulous dance between raw materials, which are usually steel, aluminum, or other alloys, and a symphony of machinery, including welding stations, cutting tools, and precise instruments.

Fabrication is the process of creating objects by assembling typically standard parts through one or more independent processes. For example, steel fabrication is the process of bending, cutting, and assembling metal to create structures. A lot of the time, metal fabrication builds larger assemblies from smaller sub-assemblies that work with easily obtained standard parts. Computer-aided designs (CAD), which are often programmed utilizing computer numerical control (CNC) technology, make this possible. Direct contact between the factory floor machinery and its operators is made possible by CNC technology.

Feasibility Report Sample On Fabrication Unit

Market Strategy of Fabrication Unit

The size of the India Fabrication Works Market is projected to be USD 20.89 billion in 2023 and is projected to increase at a compound annual growth rate (CAGR) of 6.38% to reach USD 28.46 billion by 2028.

India’s industrial industry includes metal fabrication, which has a major positive impact on the nation’s economic expansion. To create a finished product, different metal components must be cut, bent, and assembled. Among the many industries that make up the India metal fabrication market are the automotive, construction, aerospace, and energy sectors. Over the years, the industry has grown steadily due to factors like industrialization, infrastructure expansion, and technology improvements.

The metal fabrication market in India has grown significantly in the last several years. The nation’s quick industrialization, expanding infrastructure projects, and rising demand for fabricated metal goods all drive the industry. To improve their product offerings and meet changing client needs, major industry players consistently spend in research and development operations. There are many domestic and foreign competitors fighting for market share in this fiercely competitive sector.