Feasibility Report On Transformer Manufacturing

Transformer manufacturing involves producing electrical transformers, essential devices that transfer electricity between circuits efficiently. Introduced as a revolutionary technology, the transformer’s core components are coils and a magnetic core. Its innovation greatly impacts power distribution, enabling safer and more effective electricity transmission and utilization.

Introduction

Feasibility Report For Transformer Manufacturing

Transformer manufacture is an important operation in the electrical and power industries, with the goal of generating devices that allow for efficient electricity distribution and voltage management. Transformers are static electrical machines that use electromagnetic induction to transmit electrical energy between circuits, either stepping up or stepping down the voltage levels. This technology is critical in power transmission and distribution because it allows electricity to be transferred over long distances with minimal loss while also delivering proper voltage levels for safe use in homes, industries, and companies.

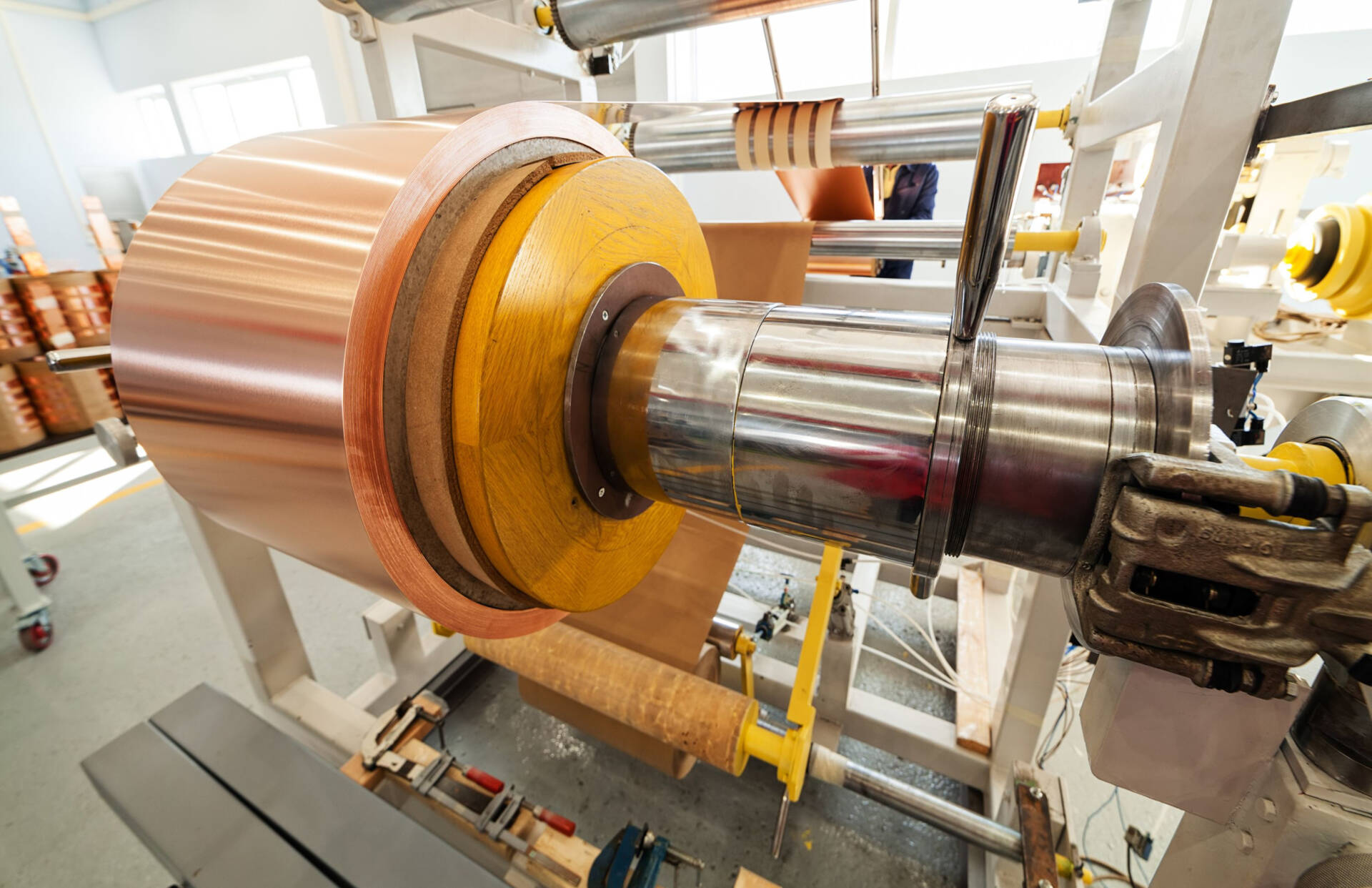

There are various critical steps in the transformer manufacturing process. The design step begins with engineers creating specifications for the transformer based on the intended application, load requirements, and climatic conditions. Following that, materials for the transformer’s core and windings are carefully selected. High-quality materials are required to reduce energy losses and assure the transformer’s dependability and lifespan. To reduce eddy current losses, transformer cores are often composed of laminated steel sheets. The winding coils are typically copper or aluminum conductors that are meticulously twisted around the core to form the primary and secondary windings. The voltage transformation ratio of a transformer is determined by the number of windings and how they are arranged.

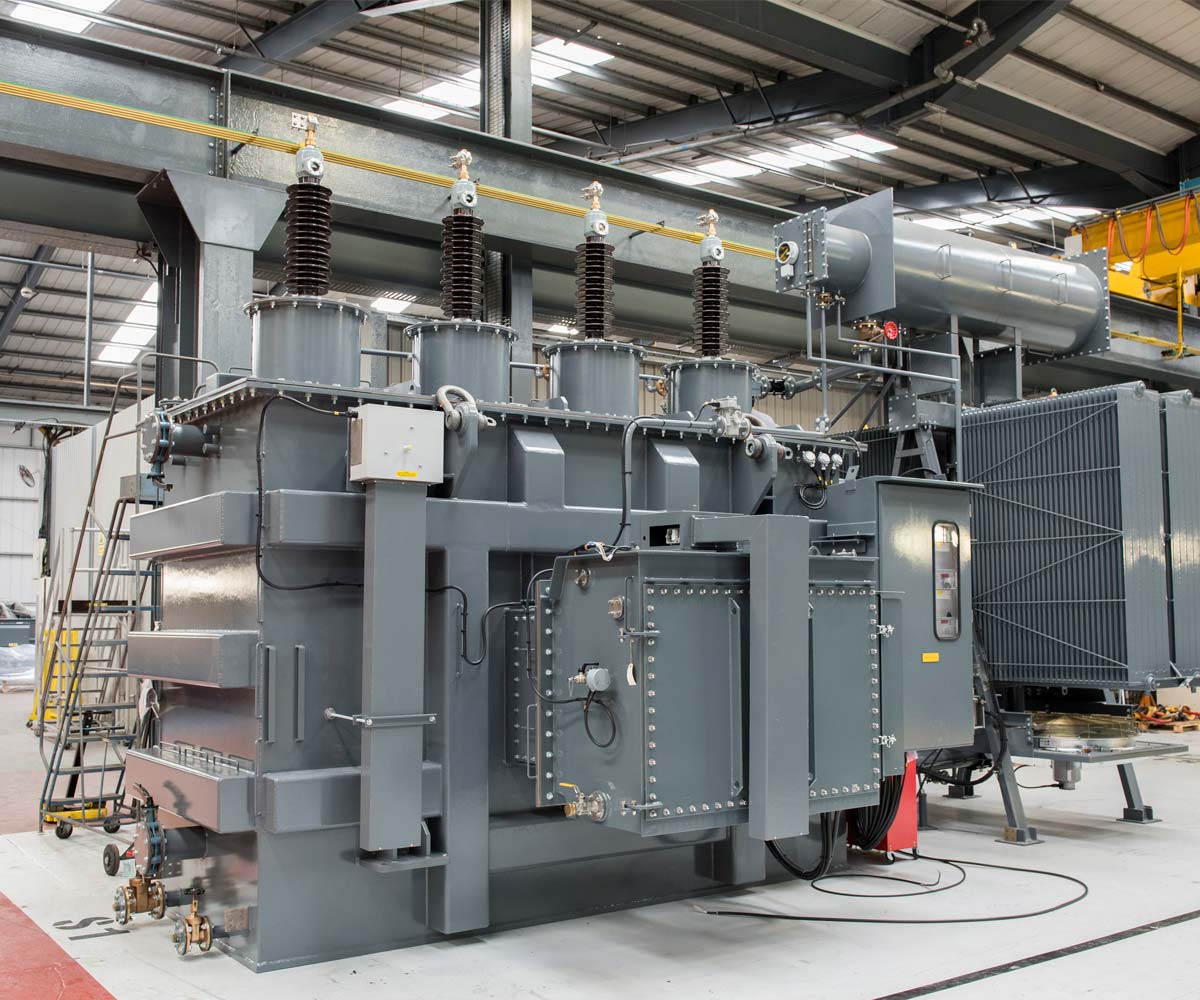

After the core and windings are constructed, the transformer is subjected to a battery of tests to ensure that it fulfills stringent quality and safety criteria. These tests include turns ratio testing, insulation resistance testing, and short-circuit testing to evaluate the transformer’s efficiency and performance. Once the transformer has passed all quality checks, it is impregnated or vacuum varnished to preserve the windings from moisture and other external conditions. The transformer is then placed in an enclosure and filled with insulating oil, which not only improves insulation but also aids in cooling.

Feasibility Report Sample On Transformer Manufacturing

Market Strategy of Transformer Manufacturing

The transformer market size was evaluated at USD 54 billion in 2022 and is expected to increase at a CAGR of 7.2% between 2023 and 2032.

The growing demand for energy-efficient power distribution networks, as well as severe government rules to reduce power waste, are boosting the market’s growth prospects. Increased innovation for the building of a centralized power distribution network, constant use of smart monitoring systems, and expansion of power distribution infrastructure are expected to open up new potential opportunities for the industry. Furthermore, most developing and underdeveloped countries are working to improve rural electrification standards and power grid penetration.

The keen interest of governments and real estate developers in procuring smart transformer solutions is expected to fuel the evolution of the transformers market. The rapid expansion of transmission and distribution networks in emerging economies due to greater investment would improve the industrial scenario.

The expansion of infrastructure development operations, supported by both public and private investments and regulatory actions, will contribute to the industry’s overall growth. There is a rising emphasis on lowering greenhouse gas emissions and implementing energy efficiency measures will create a favourable business environment for the adoption of transformer systems.

The transformer market is developing as a result of rising energy consumption and favorable regulatory reforms targeted at expanding current grid infrastructure. Upgrading and modernizing existing grid infrastructure networks, as well as an increasing emphasis on enhancing the reliability and efficiency of power distribution systems, will add to the industry’s growth.

Favorable regulatory schemes and policies, together with continued expenditures in the renovation of traditional technology, will drive business growth. Furthermore, the rapid increase of industrialization and rising energy demand, together with government attempts to improve energy efficiency, will add to the industry’s growth.