Project Report For Amino Acid Manufacturing

Introduction

Project report for Amino Acid Manufacturing is as follows.

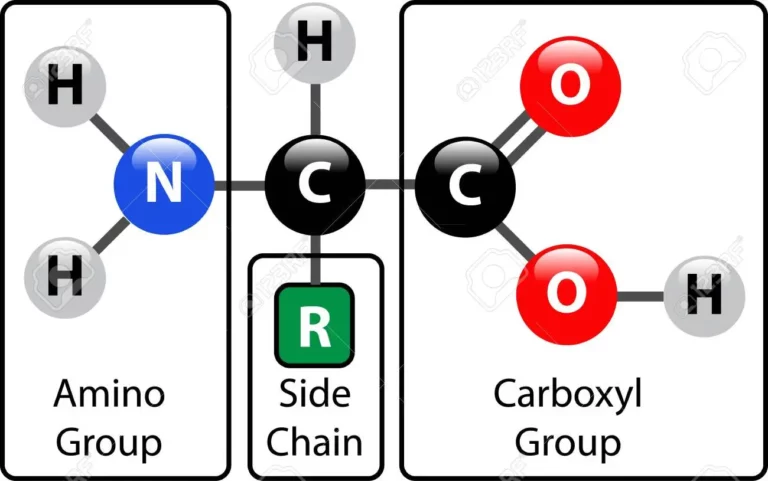

Amino acid is any of a class of organic molecules composed of a basic amino group (NH2), an acidic carboxyl group (COOH), and a unique organic R group (or side chain). Amino acid is an abbreviation for -amino [alpha-amino] carboxylic acid.

Each molecule is composed of a central carbon (C) atom, referred to as the -carbon, to which amino and a carboxyl group are attached. The -carbon atom’s remaining two bonds are generally filled by a hydrogen (H) atom and the R group.

Get Completely Custom Bankable Project Report

In the long run, rising demand for dietary supplements, combined with the expansion of the healthcare industry in countries such as India, China, Mexico, and the United States, is expected to drive product demand. Among the various amino acids, lysine and valine are gaining considerable traction with end-users.

Fermentation is used in the industrial production of the majority of L-amino acids. This technique takes advantage of the process by which microorganisms convert nutrients into the various vital components required.

Raw materials such as syrups are added to the culture media of microorganisms, and multiplying microorganisms can produce amino acids. Enzymes are critical in the fermentation-based production of amino acids.

Due to their higher amino acid concentrations and availability, plant-based raw materials such as soybean, wheat, and corn are gaining popularity. To ensure a stable supply of raw materials for production, market participants are pursuing both forward and backward integration strategies aimed at ensuring a high-quality and stable supply of raw materials.

Vertical integration provides a greater degree of certainty regarding raw material supply and enables the development of new and innovative products using existing raw materials.

Market potential

Expenses

Product Cost Breakup

Reveneue Vs Expenses

Market Trend

The global amino acids market was worth USD 21.18 billion in 2019 and is expected to expand at a 7.8 percent compound annual growth rate (CAGR) between 2020 and 2027.

The market is expected to be propelled forward by the growing demand for amino acids in the food, pharmaceutical, and nutraceutical industries. Due to the product’s ability to treat muscle soreness and sprain, as well as mental fatigue, it is widely used in dietary supplements.

Protein hydrolysis, chemical synthesis, or microbiological (biotechnological) methods can all be used to synthesise amino acids.

The method chosen is determined by available technology, raw material costs, market characteristics, the cost of running fermentation versus synthesis reactions, and the method’s environmental impact.

Biotechnological processes are widely used to synthesise amino acids. While biotechnology-based production is capital intensive, it is critical for amino acid production. Modern biotechnology is used to increase the yield of the crop.

For instance, strain enhancement is accomplished by genetic and metabolic engineering. However, it is expected that enzyme catalysis will continue to be the preferred method for the production of amino acids and their derivatives.