Project Report For Jaggery Plant

Introduction

The Project Report For Jaggery Plant Is As Follows.

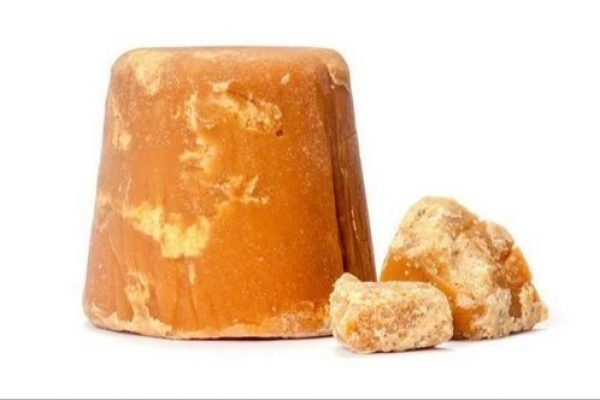

A jaggery factory, also known as a sugar cane processing plant or a sugar mill, is a facility constructed for the extraction and manufacturing of jaggery, a traditional non-centrifugal sugar. Jaggery is manufactured from the juice collected from sugar cane or other sugar-rich plants, which is then heated and hardened into blocks or cones. It is extensively used as a sweetener in a variety of culinary dishes and traditional remedies. The arrival of sugar cane to the facility kickstarts the jaggery production process. To extract the juice, sugar cane is cleaned, washed, and crushed in powerful gear known as crushers or mills. This juice includes sugars, contaminants, and fibre.

The extracted sugar cane juice is then transferred to huge containers or pans where it is continually heated and cooked. The boiling process causes the water in the juice to evaporate, concentrating the sugars and forming a thick, viscous liquid. Impurities and non-sugar components rise to the surface and are skimmed off during the boiling process. This aids in the purification of the jaggery and the removal of any undesirable elements. As the liquid continues to boil, it thickens and achieves a precise consistency. It is poured into moulds or let to cool on flat surfaces at this point, when it hardens into solid blocks or cones of jaggery.

Jaggery facilities range in size and capacity from small-scale businesses serving local markets to huge industrial plants with automated processes and high output volumes. Some jaggery factories, in addition to producing jaggery, also generate other sugar-based goods such as molasses, which is a byproduct of the jaggery-making process. Molasses may be used to sweeten foods, feed animals, and make alcoholic drinks and industrial items.

Types Of Jaggery Plant

Traditional Jaggery Plant: Traditional jaggery plants are often located in rural or small-scale settings and use manual or semi-manual procedures. These operations frequently employ rudimentary crushers or mills to extract juice from sugar cane, which is then manually boiled and solidified. They rely on trained craftsmen who are well-versed in traditional jaggery-making procedures.

Semi-Automated Jaggery Plant: Semi-automated jaggery factories incorporate some mechanisation into the production process. Mechanical crushers and automated boiling systems may be used to boost efficiency and reduce manual labour. Simple automation is frequently used in these operations for processes such as juice extraction, boiling, and jaggery moulding.

Modern Jaggery Plant: Advanced machinery and technology are used in modern jaggery factories to expedite the jaggery producing process. To optimise juice extraction, boiling, and solidification, they may include automated crushers, evaporators, and precise control systems. Modern facilities place a premium on efficiency, quality control, and increased output quantities. They may also use innovative filtering and purifying procedures to assure clean and sanitary jaggery manufacturing.

Sugar Mill Integrated: Some sugar mills include jaggery manufacturing as part of their operations. These mills are outfitted with large-scale technology and automated procedures for crushing sugar cane, extracting juice, clarifying juice, and producing jaggery. They can handle large quantities of sugar cane and generate both refined sugar and jaggery, frequently using centrifugal separation techniques to separate sugar crystals for sugar production while diverting juice for jaggery manufacture.

Market Potential Of Jaggery Plant

In 2022, the packaged jaggery market in India would be worth INR 55.6 billion. Looking ahead, the analyst predicts the market to reach INR 122.1 Billion by 2028, with a 14.1% CAGR from 2023 to 2028.

The burgeoning food packaging sector and rising consumer awareness of food hygiene and cleanliness are driving the market in India. Furthermore, the growing health concerns connected with the high incidence of diabetes, CVDs, obesity, and other diseases are shifting away from white sugar and towards jaggery. The market for packaged jaggery is also being boosted by increased knowledge of its multiple health advantages, which include tiredness relief, bone health improvement, and blood pressure maintenance.

Jaggery is a ubiquitous component used as a sweetener, flavouring agent, and colour enhancer in many traditional Indian dishes. With rising urbanisation and rising consumer living standards, there is a strong demand for processed and high-quality food goods, particularly packaged jaggery.

Project Report Sample On Jaggery Plant

Need Help?

Create 100% Bankable Project Report