Project Report For Pipe Bending Machine

Introduction

Project Report For Pipe Bending Machine is as follows.

A specific type of machine that is intended to roll and bend hollow pipes as well as sections is referred to as a “pipe bending machine” (which are thick, long metal pieces that are square or rectangular in shape). This device, sometimes referred to as a manual pipe bender or a section bending machine, may bend the sections. Cast iron and stainless steel are the types of materials that can be bent using the manual pipe bending equipment.

The rolled or bent pipes are typically employed for handlers and pressure operators, as well as in several technical services. quipment is normally operated by a person, a pneumatic system, a hydraulic assist system, or an electric servo motor. The tube may be supported internally or externally throughout the pipe bending process to protect the pipe’s cross section. The pipe does not need to be supported in operations when the shape of the pipe is flexible, but there will be some deformation in the cross section of the entire pipe and the wall thickness in various bend locations.

The bending machine operation can be carried out in a variety of ways, including manual bending and hydraulic bending. Manual bending, also known as section bending or manual bending, is the practise of bending a pipe or section by hand. The method of bending a pipe or section utilizing various hydraulics, often known as a hydraulic pipe machine, is known as hydraulic bending.

Project Report Sample On Pipe Bending Machine

Get Completely Custom Project Report

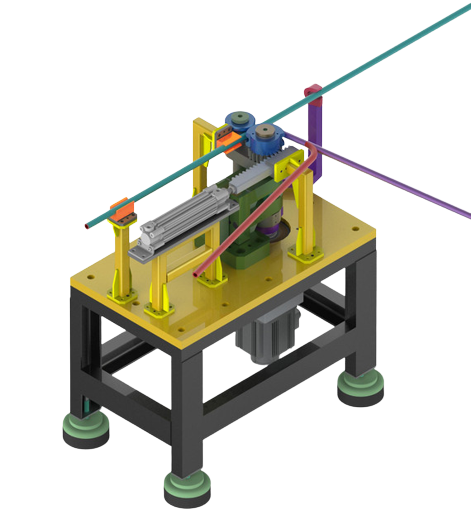

The machine’s body is its framework, to which all of its individual sections and elements will be fastened. The body’s components will be fastened together either using nuts and bolts or through welding. The rollers, which hold the component that needs to be bent between them while the bending operation is being performed, are sometimes referred to as dyers or moulderś. The revolving rods known as shafts join the rollers and the operational wheel.

Since the machine is a manual one, handling the rollers will be done by hand. The operating wheel is a sphere-shaped component that is connected to the rollers by shafts so that when it is rotated, the rollers also revolve and the operation is successful. The pipe or segment will bend with less effort. The simplicity of the construction is the main advantage. The bending machine that is manually operated is easy to operate. It can function without any coolants or hydraulics. The benefit of a pipe bending machine is that it can be used without any electrical power and just by mechanical effort.

Market Potential Of Pipe Bending Machine

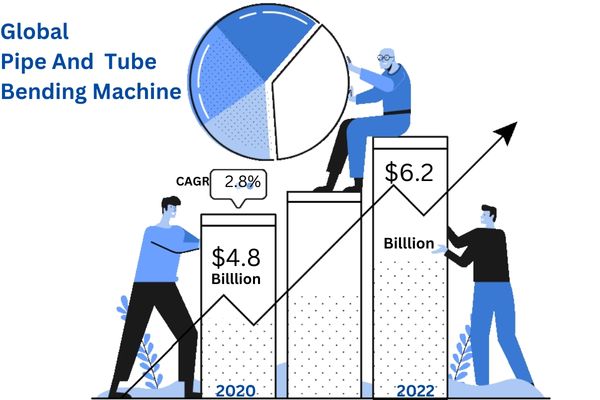

The market for pipe and tube bending machines was estimated to be worth USD 4.8 billion in 2020 and is anticipated to rise to USD 6.2 billion by 2028, with a CAGR of 2.8% from 2021 to 2028. Over the next years, the global market for pipe and tube bending machines will have revenue growth that is primarily driven by the automotive industry’s constant rise. The market is comprehensively evaluated in the report on the global pipe and tube bending machine market. The research provides a thorough analysis of the market’s key segments, trends, drivers, restraints, competitive environment, and other important elements.

The market for machines like pipe and tube bending machines has seen increased acceptance as a result of growth in the construction and automotive industries. To further generate completed items, pipes and tubes are bent using pipe and tube bending equipment. This machine has a rocker arm, a hydraulic system, a driving device, a pre-pressing device, a clamping head device, and an intermediate frequency power source. One of these is the rocker arm, which does the operation of bending the pipe to the desired radius. It is one of the essential components of the bending machine.