Project Report For Cleaning Agro Commodities

Introduction

Project report for cleaning agro commodities is as follows.

Cleaning and sorting agricultural products has been done since the dawn of time. Initially taking place at the household level, this process has now been scaled up to the industrial level in consideration of the supply and demand of all of these goods. Before any type of ingestion or usage in other products, all raw grains, pulses, legumes, oil seeds, and entire spices must be cleaned, graded, and sorted. Following harvest, particular post-harvest processes are required for cereals, pulses, legumes, oilseeds, and whole spices. These operations begin on the farm and are divided into three stages: operations at the farm level; primary processing; and secondary processing.

The following activities take place at the farm level: threshing, winnowing, drying, and storing. Cleaning, grading, sorting, and packing are all steps in the primary processing of whole agricultural products. Secondary processing, on the other hand, adds value through steps like grinding (to make flour or powder), blending, flaking, baking, roasting, puffing, etc. For further value addition, it is required to utilize cleaned and sorted grains, pulses, legumes, and whole spices.

Product & Application of Cleaning Agro Commodities

Grain, pulse, legume, oilseed, and whole spices that have been cleaned, sorted, and graded can be eaten raw or cooked. Additionally, by grinding, mixing, flaking, extruding, roasting, puffing, baking, frying, etc., for value-added products. These goods have a wide range of applications and uses.

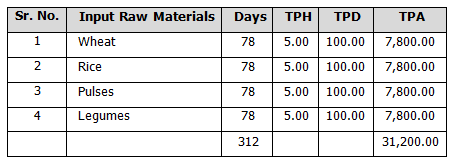

Plant Capacity & Product-Mix:

Project Report Sample On Cleaning Agro Commodities

Get Completely Custom Bankable Project Report

Manufacturing Process of Cleaning Agro Commodities

Imported grains, pulses, legumes, and whole spices are cleaned before being threshed, winnowed, and sun dried. Initial air blasts are used to remove dust, dirt, and light chaff before utilizing screens to remove large foreign contaminants. It serves as a grader on the second screen. The procedure here starts with de-stoning and continues with the separation and inclusion of shattered grains.

After being thoroughly washed, the grains are raised and placed through a de-stoner to remove stones of all sizes. The destoned grains are then separated using specific gravity to differentiate light foreign grains of the same size.

Market Potential of Cleaning Agro Commodities

The global agriculture market grew from $11,109.32 billion in 2021 to $12,152.6 billion in 2022 at a compound annual growth rate (CAGR) of 9.4%.

Expenses

Product Cost Breakup

Reveneue Vs Expenses

Market Trend

India is the world’s second largest producer of wheat, rice, and coarse grains, respectively (maize, barley, sorghum). Since 1961, India has been the greatest producer of beans, chick peas, and pigeon peas in the world, accounting for 35% of global production. India’s main problem is its inadequate post-harvest, storage, and logistical infrastructure. In order to produce value-added products like puffed cereals, cereal bars, and complete cereal foods for infants, as well as extruded, roasted, and healthy cereal products, it is necessary to increase farm level and primary processing of cereals, legumes, pulses, oilseeds, and whole spices for daily consumption.