Project Report For Dal Mill

Introduction

Project Report For Dal Mill is as follows.

A dal mill is used to process dals such as masur, tur, urad, and chana, among others. This procedure involves milling, grinding, grading, polishing, checking, cleaning, making flour, and removing stones and dal dust.

Dal milling is a booming industry in India. Based on the output of production. dal is a well-liked and widely-used food grain in India. After rice and wheat, dal milling is the third-largest food processing sector in our nation. The state of Madhya Pradesh is the leader in dal production. 23% of the nation’s total production of pulses is produced in the state. Rajasthan, Maharashtra, Gujarat, Tamil Nadu, Odisha, Bihar, and West Bengal are additional states that produce a significant amount of pulses. Pulse milling was once a small-scale agricultural activity, but as food demand increased, it has recently become a sizable commercial endeavor.

There are numerous types of equipment needed to create a dal mill.

Grains that are bigger or smaller than the typical material size are cleaned of pollutants using the reeling machine. Since reel cleaning equipment has several alternatives, it is used in many different settings. Conveyor systems are mechanical tools that provide the more effective material transfer. All conveyor systems feature a frame that holds wheels, rollers, or a belt that moves material from one place to another. Conveyor systems come in a range of sizes and designs.

Get Completely Custom Bankable Project Report

The Emery Roller also referred to as a pulse splitter, is a device for de-husking pulses. They are employed in numerous pulse mills. Polishing is a type of value addition carried out to raise customer attractiveness. Several methods, including leather, oil/water, and nylon polish, are used to polish dal.

The local government is where the license can be obtained. The registration for the Dal Mill company needs to be completed under the industrial base. The owner of a dal mill must register with the Food Safety and Standards Authority of India (FSSAI). Goods and Services Tax registration is also necessary for It Mill to operate effectively. The company owner must register for Employee State Insurance (ESI) and Employees Provident Fund (EPSF) (EPF).

Market Potential of Dal Mill

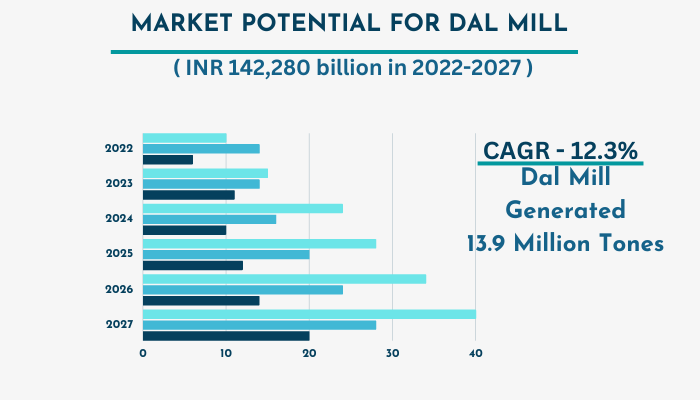

India’s agriculture industry was worth INR 71,220 billion in 2021. According to research, the market will increase from 2022 to 2027 at a compound annual growth rate (CAGR) of 12.3%, reaching INR 142,280 billion.

India is the world’s top producer of pulses (25 percent of total output), consumer of pulses (27 percent of total consumption), and importer of pulses (14 percent). Around 20% of the land in the country is planted with pulses, which produce between 7% and 10% of the nation’s total grain production. The dal milling industry is one of India’s major agro-processing industries. Dal mills process 75% of the 13.19 million tones of pulses that are generated in the country each year.

Pulses are often eaten as one of the varieties of meal preparations after being turned into de-husked split pulses that can be prepared quickly. Large-scale dal milling industries require substantial capital investments, power supplies, and raw material

supplies to achieve economic stability and produce high-quality products; in contrast, small- or extremely tiny-scale units produce products with lower quality and yield when compared to large-scale dal industries. Even while some small-scale machines, like a micro dal mill, do various tasks like de-husking pulses satisfactorily, several machine parameters, a low capacity, and particularly wet pre-milling treatment constitute restrictions for these units. However, in these modest or lower scale factories, only pulses that are more difficult or simpler to mill, like toor dal, are used