Project Report For Gummed Paper Tape

Introduction

Project report for gummed paper tape is as follows.

Gummed paper tapes offer protection against theft and tampering since they cannot be torn off. These are simple to adhere to and provide boxes and packages with an appealing appearance. These tapes can be tastefully printed in any colour of choice, with great advertising value, originality, and recognition.

Almost all of the raw ingredients, such as Kraft paper, adhesives, cores, printing inks, and other supporting components, are locally available for the production of gummed tapes.

The primary raw materials needed to make gummed paper tape are rolls of Kraft paper, standard-quality animal glue, glycerin preservatives and other chemicals, plastic cores, reels of bituminized packaging paper, labels, etc.

Product & Application of Gummed Paper Tape

Papers with patterns and different colours that have adhesive on one side for easy application. Coated or uncoated book paper with a gummed side is used for tapes, stickers, labels, stamps, and seals. Gummed paper tape can also be used with a variety of other materials, including gummed paper, ink pads, office machinery paper, pastels, pencils, pens, perforated papers, postcards, print cartridges, printed paper, propelling pencils, refillable pens, ribbons, rolling ball pens, rubber stamps, self-adhesive papers, stationery sets, and typewriter ribbons.

Project Report Sample On

Gummed Paper Tape

Get Completely Custom Bankable Project Report

The Benefits of Gummed Paper Tape

1. Strength :- As previously stated, when the natural glue adhesive is applied, it becomes moistened, resulting in a full bond with the carton. This is due to the fact that the water-activated adhesives permeate the carton liner, causing the tape to become part of the box. By our standards, this is an outstanding seal.

2. Tamper-evident :-The ability to make packaging tamper-evident is quite beneficial, especially when valuable products are involved. When gummed paper tape is placed to a box, it forms a lasting bond. This indicates that as a result of attempting to detach the tape from the carton, the carton is damaged and shows signs of tempering.

3. Cost-effective :- Gummed paper tape is a low-cost way to seal your cartons. Only one strip is required for a safe and secure seal where the tape forms a permanent bond with the carton. In contrast to other regularly used tapes, one strip is rarely sufficient to seal a box with confidence that it will remain closed.

4. Eco-friendly :- Gummed paper tape is completely recyclable because it is manufactured from renewable natural materials. Many businesses that utilise gummed paper tape find that it improves their green credibility with clients while also helping to keep the environment green.

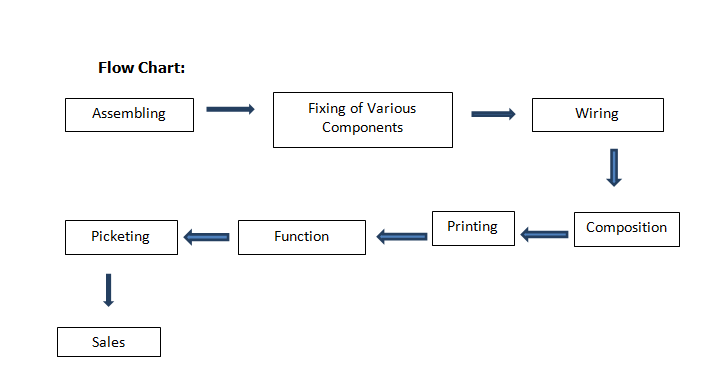

Manufacturing Process of Gummed Paper Tape

A water-soluble adhesive mixture is consistently applied to one side of the reels of Kraft paper using a coating machine. It is coiled after being dried in a drying chamber. After that, the coated rolls are slit into different sizes (width and length). The gummed tape reels’ untreated side can be printed on if necessary.

Market Potential Of Gummed Paper Tape

The global market for the gummed tape was estimated to be worth USD 3,704.16 million in 2021 and is anticipated to grow to USD 5,092.46 million by 2029, recording a CAGR of 3.6% over the projected period of 2022–2029

Expenses

Product Cost Breakup

Reveneue Vs Expenses

Market Trend

BOPP adhesive tape is taking the place of paper gummed tape. However, because it is inexpensive, simple to use, and readily available, paper-gummed tape will continue to be used. In comparison to other economic sectors, the growth rate of the consumer industries is relatively strong. Due to the country’s rising GDP and potential for exports, the long-term trend is favourable.

The market potential of gummed paper tape is significant, as more and more businesses are seeking sustainable and cost-effective packaging solutions. One of the major drivers of this market is the increasing demand for e-commerce and online shopping. With the rise of online shopping, there is a greater need for secure and reliable packaging solutions that can withstand the rigors of shipping and handling. Gummed paper tape is an ideal solution for this, as it offers a strong and secure seal that can protect packages during transit.

Another factor driving the market potential of gummed paper tape is the growing focus on sustainability and environmental responsibility. Many businesses are looking for ways to reduce their carbon footprint and minimize waste. Gummed paper tape is a great option in this regard, as it is made from renewable materials and can be easily recycled or composted. This makes it an attractive option for businesses looking to improve their sustainability credentials.

The market potential of gummed paper tape is also influenced by the increasing availability of customized options. Many manufacturers now offer custom printing and branding options, allowing businesses to create unique and personalized packaging solutions that can help them stand out from the competition. This is particularly important in the e-commerce space, where businesses need to differentiate themselves in a crowded marketplace.