Project Report For Lathe Machine

Introduction

Project Report for Lathe Machine is as follows.

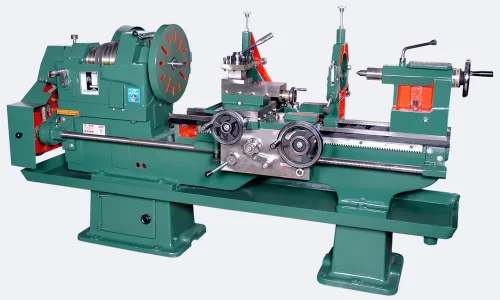

A lathe is a machine tool, metal may be taken out of a workpiece to give it the correct form and size. The use of lathes includes glass processing, thermal spraying, metalworking, wood turning, metal spinning, and part recycling. With the use of a lathe, numerous more tasks can be carried out, including grinding, cutting, knurling, drilling, and deforming, and these instruments are used to make items that are symmetrical about an axis of rotation.

A lathe is a device that rotates a workpiece around its axis to carry out a variety of operations, including cutting, grinding, knurling, drilling, or deforming, facing, and turning. It can also be used to rotate a tool while it is being applied to the workpiece to produce objects that are symmetrical about the axis. Although they were first intended for machining metals, their intrinsic adaptability has allowed them to be employed in a broad variety of applications and materials with the introduction of plastics and other materials.

Functions Of Lathe Machine

- The primary purpose of a lathe is to remove superfluous material in the form of chips by spinning the workpiece against a stationary cutting tool.

- This is done by clamping the work firmly and solidly to the machine, rotating it against the cutting tool, and then removing the metal from the work.

- To cut the material properly, the tool needs to be harder than the work piece’s material, be rigidly held on the machine, and be fed or advanced in a clear direction in relation to the job.

Uses of Lathe Machine

Most woodworking and machine shop tools are easily identifiable. Drills, punches, and vises are very simple instruments that have a specific purpose. Other machines may be more intricate, and lathes, especially high-end ones, fall into this category.

A lathe is, at its core, a simple apparatus meant to hold a segment of material while a turning tool carves, cuts, or moulds it. This is referred to as the workpiece. A lathe, unlike a conventional vice, not only holds but also spins an object. This allows the machine’s head to move along the workpiece while holding multiple cutting tools to shape it.

Industrial lathes can be extremely large, but a toolroom lathe is often a smaller machine tool. Because of its versatility, a metal lathe is a mainstay of many small machine shops or tool-and-die shops. Outside of the machine shop, many professionals and hobbyists rely on lathes. A lathe can be used to make parts for an antique car.

Get Completely Custom Bankable Project Report

Market Potential Of Lathe Machine

The Lathe Machines Market was anticipated to be worth US$ 10.68 billion in 2021, with total sales likely to grow at a 1.8% CAGR between 2021 and 2029, reaching approximately US$ 12.32 billion.

One of the key drivers boosting market growth is the rising trend of industrial automation and precise production since lathe machines increase product consistency and strengthen the value chain. Additionally, due to their high speed, accuracy, and low running costs, lathe machines are becoming more popular in the production of various medical implants and equipment.

In addition, the growing need for safe, fuel-efficient cars is encouraging the use of lathe machines to shape various car parts. Many multinational companies are locating their production operations in developing nations like China and India due to the availability of technical know-how, cheap labor, and low-cost raw materials.

The Indian lathe manufacturing industry faces several challenges, including a lack of skilled labor, high import duties on raw materials, and the availability of low-cost alternatives from other countries such as China. However, the government has been taking steps to address these issues, such as promoting vocational training programs to develop a skilled workforce and reducing import duties on certain raw materials.