Project Report For Leather Belt Manufacturing

Introduction

Leather belt manufacturing project report is as follows.

A belt is a flexible band or strap that is worn around or near the natural waist and is typically made of leather, plastic, or heavy cloth (as far down as the hips). The ends of a belt are unattached, and a buckle connects one end to another part of the belt, at or near the other end, to form a loop. Frequently, the resulting loop is smaller than the hips. Due to the wide range of waist sizes, belts come in a variety of lengths, and most belts can be adjusted at the buckle to fit the wearer’s waist. Belts are used in a variety of ways, including to secure or hold up clothing such as trousers, shorts, and skirts, to carry objects such as tools and weapons, and to define or accentuate the waist.

Belts can also be made of braided leather, tooled leather, suede, leather-backed ribbon, canvas, webbing, rope, and other materials. Leather is the most commonly used belt material because it can be bent, folded, and tightened without becoming damaged. Genuine leather belts will also age with the wearer, providing a comfortable and tailored fit. Cowhide leather is commonly used to make belts. Full-grain leather is the best cowhide leather available and is recommended for its durability even with daily use. Calfskin is soft and supple, making a full-grain calfskin belt among the finest available.

Project Report Sample Of

Leather Belt Manufacturing

Get Completely Custom Project Report

Market Potential Of Leather Belt Manufacturing

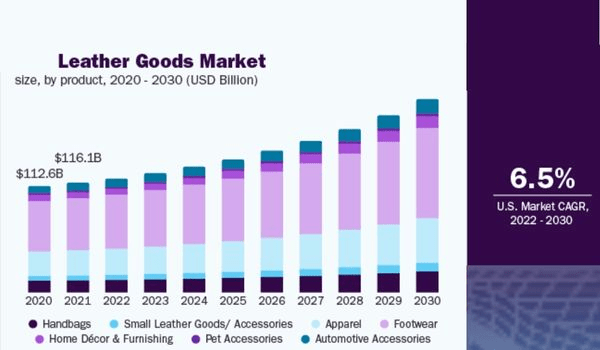

The global leather goods market is expected to grow at a compound annual growth rate (CAGR) of 6.9% from 2022 to 2030, reaching USD 407.92 billion in 2021. The primary drivers of the market are rising consumer disposable income, higher living standards, changing fashion trends, and increased domestic and international tourism. Rising demand for comfortable, trendy, and fancy leather apparel, footwear, and accessories, as well as increased brand awareness, are expected to benefit the industry.

Business Making Leather Belts Needs a License –

- Trade License

- Current Account

- Firm Registration

- GST Registration

- IEC Code

- Trade Mark

- Udyog Aadhar MSME Registration

The demand for leather belts is also driven by changing fashion trends. As consumers become more fashion-conscious, they are willing to pay a premium for high-quality, stylish leather belts. In addition, the durability and longevity of leather make it a popular choice for consumers who are looking for a long-lasting product.

The market potential of leather belt manufacturing is the availability of raw materials. Leather is a natural material that is widely available, making it a cost-effective and sustainable option for manufacturers. Moreover, the leather industry is highly regulated, ensuring that the leather used in the manufacturing of belts is of high quality and meets international standards.

Manufacturing leather belts is a relatively simple process that does not require sophisticated machinery or technology. This makes it a viable option for small and medium-sized businesses that want to enter the fashion industry. Additionally, with the rise of e-commerce and online marketplaces, manufacturers can easily sell their products to customers worldwide, expanding their reach and increasing their potential customer base.

The availability of a large labor pool and several programs for skill development targeted at creating jobs in the leather sector are enhancing this industry’s comparative advantage. The government intends to train some 200 000 people a year for the leather sector.

Additionally, the Footwear Design and Development Institute (FDDI) seeks to expand into the foreign market through design and fashion innovations. Due to the government’s decision to automatically accept 100% of FDI, the sector is anticipated to flourish.

The government also wants to increase the sector’s production through technological advancement. In the next ten years, productivity in the leather sector is expected to nearly quadruple according to the government’s key Integrated Development of Leather Sector (IDLS) plan.