Project Report For Shampoo Manufacturing

Introduction

Project report on shampoo manufacturing is as follows.

The shampoo is a hair care product that is used to clean hair and is normally in the form of a thick liquid. Shampoo should always be used to dampen hair, massage it into the scalp, and then thoroughly rinsed it out.

Shampoo Manufacturing Process

The liquid shampoo is made by heating triethanolamine, lauryl sulfate, and stearic acids to around 65°C. Water and preservatives are also heated to 65 degrees Celsius. The two solutions are blended and then refrigerated. After that, you’ll need to add the perfumes. As a consequence, you will receive the finished shampoo. The shampoo is subsequently moved to the bottling and packaging division. To bottle the shampoo, use the suitable automatic filling machine.

Procure Raw Materials

The raw materials utilized vary based on the specification. However, a list of basic raw components is provided below. The following are the most important raw material requirements:

Triethanolamine Lauryl Sulfate

Sulfonated castor oil

Ethyl Alcohol.

Oleic acid/Stearic acid.

Coconut oil.

Colour, perfumes & preservations.

The Raw materials can be purchased from local wholesalers or directly from manufacturers. In addition to these basic supplies, you’ll need packaging consumables such as plastic bottles, labels, shrink jackets, and outer corrugated boxes.

Packaging is critical in the cosmetics industry. As a result, you must use extreme caution. Include the product’s name as well as the manufacturing address. List the net contents of the ingredients used in the product’s manufacture as well. Include the following information: ingredients, intended use, batch number, manufacture date, and MRP.

Benefits of Shampoo -

Resists overly dry or oily hair: Good hair care products should not contain the elements that can result in dry or oily-looking hair. Quality shampoo and conditioner will cleanse the hair while balancing the environment on the scalp so that the hair looks clean and healthy rather than oily or dry.

Growth of hair in aids: Your hair and scalp will be considerably healthier if you stop using products that constantly damage your hair. New hair growth can start and grow out of the shaft easily when the scalp is not clogged by product accumulation, is not overly greasy, or is not dry and flaky. More hair will develop as a result of this since more hair follicles will be able to grow.

Able to stop dyed hair from fading: Shampoos are appropriate for all hair types and are the best choice for people with dyed or permed hair because they clean without removing the color or structure of the hair, helping to keep the color and style looking newer and longer.

They moisturize naturally: Shampoos and conditioners typically contain pure and nourishing moisturizers like gels, oils, and various types of butter produced from leaves, nuts, seeds, or kernels. A few of the common moisturizers that can be included in shampoos and conditioners include Aloe Vera, Coconut Oil, and various kinds of butter, such as Cocoa Butter.

Project Report Sample Of

Shampoo Manufacturing

Get Completely Custom Bankable Project Report

They are allergen-free: Shampoos and conditioners contain only natural components, which contribute to their hypoallergenic compositions and enable them to be used on all skin types, even sensitive or allergy-prone ones. Shampoos and conditioners with natural fragrances are kinder to those who have sensitive noses because of their softer scents.

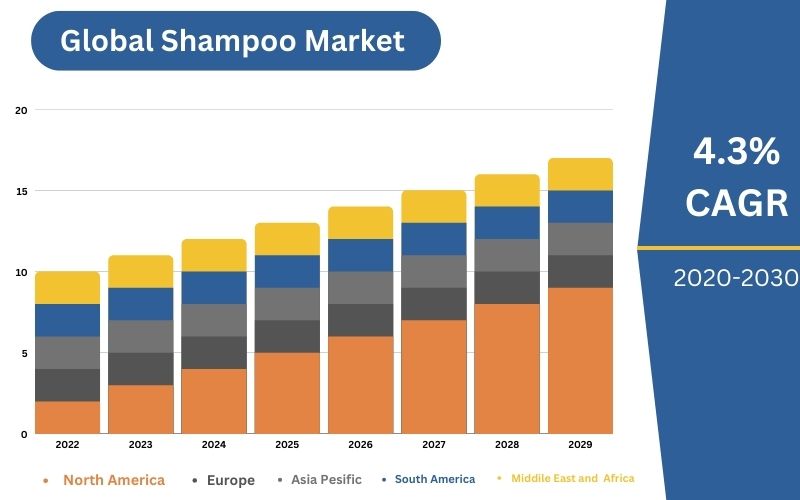

Market Potential Shampoo Manufacturing

The market for hair shampoo was valued at $29,700.7 million in 2020, and it is anticipated to increase by 4.3% between 2021 and 2030 to reach $44,378.8 million.

The shampoo market in metropolitan India has changed significantly since the 1960s when it was still considered a lifestyle item. Garnier and ITC Ltd. are just two of the many domestic and international businesses that have entered the competition. Businesses benefit from the substantial room for growth at both the high and lower ends of the market. The majority of this industry is composed of the subcategories of shampoos, hair oils, hair serums, hair conditioners, hair colorants, and hair gels.

Setup & Equipment for a Shampoo Manufacturing Plant – Some of the most fundamental machine specifications are as follows: S.S. 304 open tank with slow speed stirrer for shampoo, mixing, cooling, bottle filling and sealing, weighing, and, lastly, research and development (R&D) equipment.

Locate a location that will work for your industrial business. Additionally, you’ll need to set up necessary utilities like power and water. You will want 4000 square feet to run full-fledged manufacturing.

Shampoo manufacturing process: To create liquid shampoo, triethanolamine, lauryl sulfate, and stearic acids are heated to about 65°C. The preservatives and water are heated to 65° Celsius as well. After combining the two solutions, they are chilled. The smells must then be added after that. You’ll therefore receive the finished shampoo. Then the shampoo is delivered to the packaging and bottling area. Use suitable automatic filling equipment to bottle the shampoo.