Project Report For Toilet Soap Manufacturing Unit

Introduction

Project report for Toilet Soap Manufacturing Unit is as follows.

The soap industry in India has a long history, dating back to 1889. The use of soap or soap-like cleaning agents has always been linked to man’s innate desire to keep his body and other belongings clean. Soap removes slag from the skin, giving it a beautiful radiance.

Oil and fats are the primary raw materials used to make soap. The grade and type of soap vary depending on these raw components. The raw components must be of high quality, and the completed product must have a balanced pH because the foam may enter the eye.

Toilet soap is created by combining liquid lipids (such as vegetable or animal fat) with an alkali such as sodium hydroxide (also called lye). The process is known as “saponification,” which literally means “to transform fat or oil into soap by interaction with an alkali.” Sodium hydroxide and water evaporate from the product during the curing phase, leaving only wonderful soap.”

The practice of adding liquid fats to the soap after saponification is known as “superfatting,” and it is famous for its rich, moisturizing effect. Clear soaps will contain glycerin and sorbitol (a sugar alcohol with emollient characteristics), whereas antibacterial soaps would typically contain triclosan, a chemical that destroys germs and helps prevent fungus growth.

Every home employs a simple production process with high return soaps. The demand for antibacterial soap with a moisturiser is enormous. The market extends from remote villages to major cities. The industry is profitable and employs a large number of people.

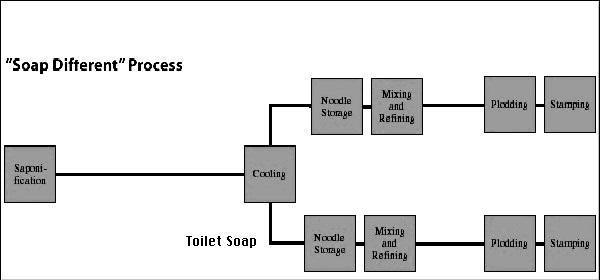

Manufacturing Process of Toilet Soap Manufacturing Unit

The beauty toilet soap can be prepared or manufactured in two steps: preparation of the soap base and final product soap base. The specifications are carried out when manufacturing the soap base, which is done by either remitting and perfuming or milling. Fat of superior quality should be used.

Weigh the fat oil and lye (sodium- hydroxide) accurately; if the lye is weighted too much, the soap will be hard and irritating to the skin; if the lye is weighed too little, the fat will not be saponifed adequately. Melt the oil fat in a kettle and strain it to remove any impurities. Now gently pour in the caustic soda lye and stir continually until the oil is completely saponified. Add the perfume and colours and pour.

Toilet soaps have become a necessity for people in modern life as people’s awareness of health and hygiene has grown. Urbanization and industry developments have led to an increase in demand as well as an improvement in product quality.

With the introduction of new technologies and sophisticated manufacturing, development processes have improved, and as a result, the markets are flooded with a wide range of soaps that differ in both physical and functional attributes. Toilet soaps are broadly classified into several types of soaps, including- Oily Soap, Dry Soap, Sensitive Soap, Normal Soap, Baby Soap, Antibacterial Soap, Glycerin Soap, Olive Oil Soap, Herbal Soap Bath soaps are personal care products made from alkalis like caustic soda and caustic potash.

Glycerin, animal or vegetable fats, propylene glycol, allantoin, sodium laureth sulphate (SLS), and triethanolamine are also present. They help to unclog pores, remove dirt and debris, and condition the skin. Bath soaps are in high demand because they help to maintain an individual’s overall hygiene and are available in powder, bar, flakes, or liquid form.

Project Report Sample On Toilet

Soap Manufacturing Unit

Get Completely Custom Bankable Project Report

Market Potential Of Toilet Soap Manufacturing Unit

In 2022, the worldwide bath soap market had a value of $22.7 billion. Looking ahead, IMARC Group projects that the market will increase at a compound annual growth rate (CAGR) of 4.1% from 2023 to 2028, reaching US$ 29.3 billion.

Expenses

Product Cost Breakup

Reveneue Vs Expenses

Market Trend

The global bath soap market report by IMARC Group includes an analysis of the key trends in each sub-segment, as well as forecasts at the global and regional levels from 2023-2028. The market has been segmented in our report based on product type, form, and distribution channel.

The market is growing and typified by severe competition among large brands. There has been a rising tendency towards value-added products in recent years. As a result, the market’s major manufacturers have been releasing novel product versions aimed at a certain consumer category, such as children. Various producers are also focusing on improving the product’s aesthetic look and, as a result, are heavily spending in designing appealing and vibrant packaging designs in a variety of formats.

Wipro Consumer Care Limited, Godrej Consumer Products Ltd, Hindustan Unilever Ltd, and Reckitt Benckiser (India) Pvt. Ltd, ITC Ltd, Colgate Palmolive (India) Ltd, Jyothi Laboratories Ltd, Patanjali Ayurveda, The Himalaya Drug Company, and Karnataka Soaps and Detergents Ltd are major players in the India Soap market. To remain competitive in the market, market leaders are continually developing new items.