Project Report For Solvent Extraction Plant

Introduction

Project Report For Solvent Extraction Plant is as follows –

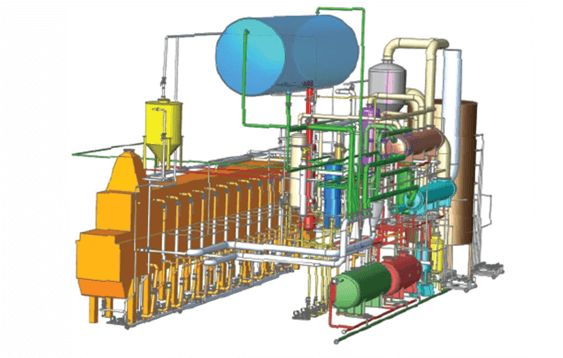

Solvent extraction is used to separate substances by how well they dissolve in two different immiscible liquids. To create oil of great quality, however, one of the most contemporary approaches is to use a solvent extraction plant to recover oil from materials that contain oil at a very low temperature while under vacuum.

Oil is derived from oil seeds including soybean, sunflower, cottonseed, and other oil seeds as well as oil cakes like mustard cake, groundnut cake, and rice bran using solvent extraction plants. Following extraction, the materials are put via a hopper and onto a conveyor.

It creates a solid bed there, preventing solvent vapours from escaping. Up until about 95% of the oil’s original content has been removed from the raw materials, the entire extraction process is carried out in several phases. The extractor is kept at a temperature of 50 to 60 oC and slightly below atmospheric pressure during the procedure.

Solvent extraction is used to get rid of the majority of a seed’s oil. Extraction is done on pre-prepared seeds or, more often than not, the cakes made from pre-pressing seeds with high oil content. Oil is extracted using chemicals in solvent extraction plants.

Project Report Sample On Solvent

Extraction Plant

Get Completely Custom Project Report

In this extraction method, hexane is used to treat the source materials before the oil is extracted, resulting in a miscella-like oil-in-hexane solution. Through the processes of condensation, evaporation, and distillation of miscella, the substance’s absorbed hexane is recovered. Hexane is utilised in the extraction process due to its low boiling point (67°C) and excellent solubility of oils and fats.

It is possible to extract solvents by crushing seed. The oil in the pulverised seed or cake is then released by purging or washing the material with a petroleum distillate (hexane is the most frequent chemical employed). The oil is heated in an enclosed chamber to “flash off” the solvent. The oil/solvent mixture is then heated to 212° F (100° C) to distil the solvent out of the mixture.

Market Potential Of Solvent Extraction Plant

In 2020, the market for botanical extracts was worth USD 4.65 billion. At a CAGR of 9.6% throughout the projected period, the market is anticipated to increase from USD 5.05 billion in 2021 to USD 9.62 billion by 2028. (2021-2028).

The worldwide market for solvent extraction systems is anticipated to reach USD million in value in 2022 and USD million in 2028, with a CAGR of % over the forecast period of 2022–2028. Soxhlet Extractor, which accounted for% of the worldwide market for solvent extraction systems in 2021, is expected to reach a value of USD million by 2028 while expanding at a revised% CAGR from 2022 to 2028, fully taking into consideration the economic shift brought on by this health issue. While over this projected period, the sector for the environment has changed to a % CAGR.

Region-specific market analysis and market size data are provided for the global solvent extraction system market (countries). The Solvent Extraction System market is divided into the following regions: the United States, Europe, China, Japan, Southeast Asia, India, and the Rest of the World.

The research provides historical 2017–2028 Solvent Extraction System market forecast data by region. Additionally, it provides market size and revenue forecasts for the 2017–2028 period by players, type, and application sector.