Project Report For WPC board Manufacturing

Introduction

Project report for WPC board Manufacturing is as follows.

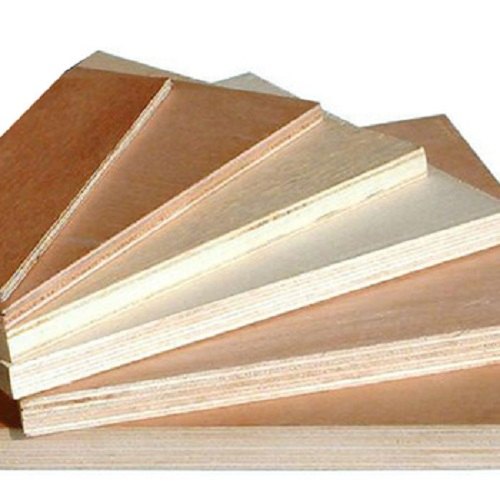

WPC stands for Wood Plastic Composite Board in its full form. WPC board is a high-strength, long-lasting material that may be used in building construction, household furnishings, decks, and other applications.

The endeavour is being stepped up to develop environmentally friendly construction materials that cause less environmental impact during their manufacture and usage. WPC board, which stands for Wood Plastic Composite Board, is a composite material manufactured by fusing plastic and wood fibres together.

Project Report Sample On WPC

Board Manufacturing

Get Completely Custom Bankable Project Report

Wood Plastic Composite (WPC) is an element made from a range of natural wood blends and plastic fibres, peanut hulls, pulp, bamboo, sawdust, and odd woodworking materials, such as bark, that are blended with plastic powder for a variety of tasks.

WPC stands for Wood Plastic Composite Board in its full form. WPC board is a high-strength, long-lasting material used in the construction of buildings and other applications.

It is made by combining finely ground fibre and wood particles with thermoplastic components. Plastic material composites may be used to make it. WPC board, which is made out of wood and plastic, may be used to cover furniture with a high-strength coating.

WPC (Wood Plastic Composite Boards) contains 70% virgin polymer and 15% wood powder, with the remaining 15% being additive-chemical.

Decks, landscaping, floors, windows, fences, doors, rails, and internal or exterior wall cladding are all examples of WPC applications.

Wooden fibres, waste materials, and thermoplastics are used to make WPC boards. They combine nicely to create a substance with a rich consistency that can be shaped and sliced into various dimensions.

Market Potential Of WPC Board Manufacturing

Expenses

Product Cost Breakup

Reveneue Vs Expenses

Market Trend

Wood-Plastic Composites are materials created by mixing wood powder or woody biomass from agricultural leftovers with polymers like polyethene or polypropylene in an extruder.

This material has been under development for more than four decades, with WPC board makers continuing to spend extensively on advanced research. Since its creation, the United States of America has seen the largest use of wood-plastic composites, mostly for outdoor applications such as deck flooring and railings, to mention a few. WPC is used in a variety of sectors, including shoe manufacture and vehicle manufacturing, in addition to being a material for furniture.

Wood-Plastic Composites as a market is rising slowly but gradually, due to the fact that this material is seen to be more environmentally friendly and has a slew of other benefits, as we’ll see below.

As per a study conducted in 2017, the worldwide WPC market generated approximately $4 billion in sales. The market is predicted to increase at a 9.3 percent annual pace. While WPCs are now most popular in the United States and Europe, WPC and PVC board makers in growing countries such as India and China have a lot to look forward to. Factors such as rising urbanization, the expansion of nuclear family structures, and a push for environmental awareness will fuel market demand and growth.