Detailed Report On Welding Rod Manufacturing

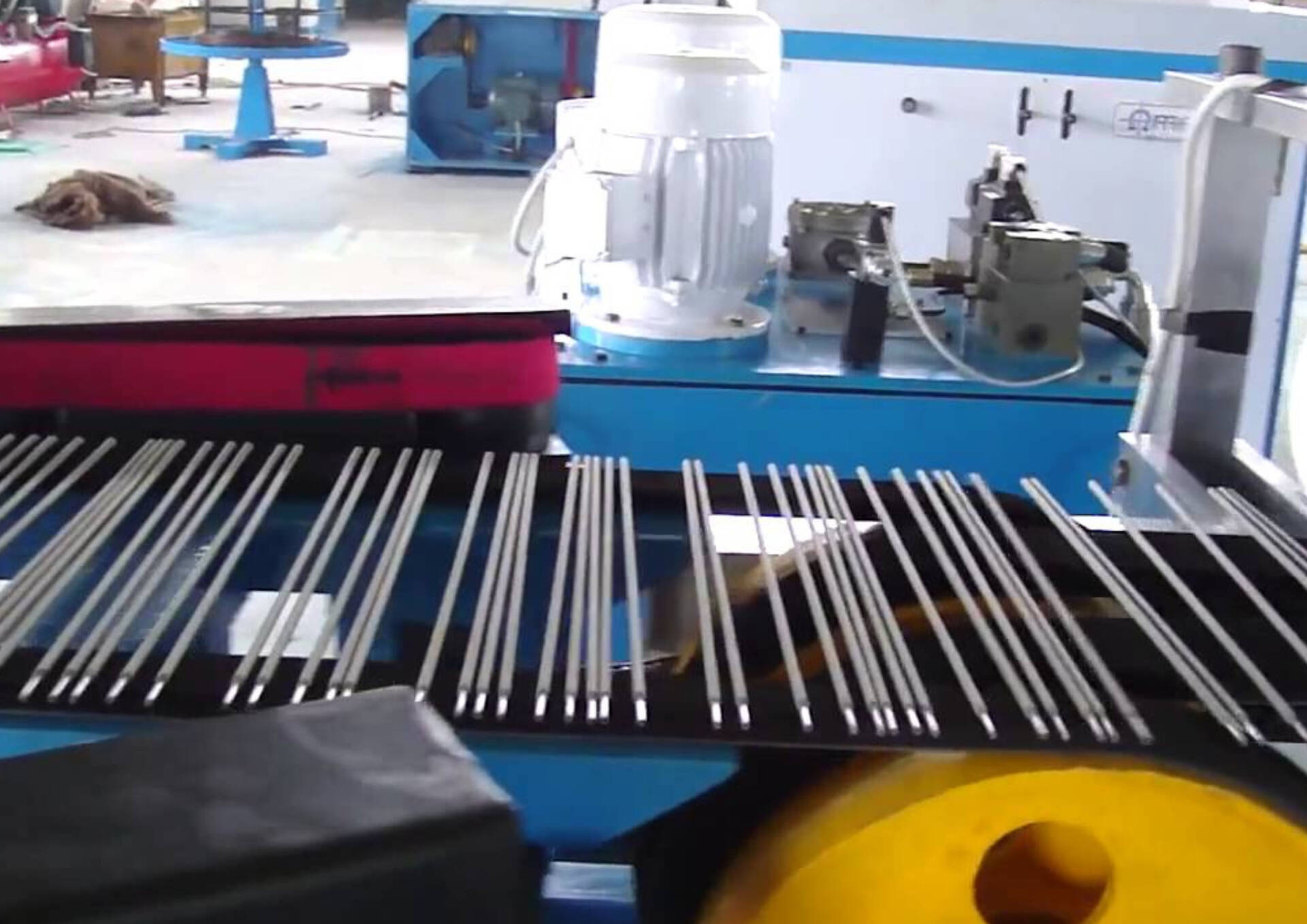

Welding rod manufacturing involves the production of consumable electrodes used in welding processes. These rods, coated with flux, melt to join metals together when heated, playing a pivotal role in construction and manufacturing.

Introduction

Detailed Report on Welding Rod Manufacturing is as follows.

Welding is a manufacturing technique that employs fusion to join materials, most often metals or thermoplastics. This is often achieved by melting the workpieces and adding a filler material to create a pool of molten material (the weld puddle) that cools to form a strong connection, but pressure can also be used in conjunction with or instead of heat to make the weld. Soldering and brazing, on the other hand, involve melting a lower-melting-point material between the workpieces to form a connection without melting the workpieces themselves. There are several forms of welding created, including gas welding, resistance welding, energy beam welding, solid-state welding, and so on.

Welding can be done using a gas flame, an electric arc, a laser, an electron beam, friction, and ultrasound, among other energy sources. Welding, while commonly associated with industry, may be conducted in a range of environments, including open air, underwater, and in space. Welding is still harmful regardless of location, and precautions must be taken to avoid burns, electric shock, toxic fumes, and excessive UV radiation exposure.

the welding rods are subjected to extensive testing, which includes chemical composition, mechanical characteristics, and coating integrity assessments. After that, the final welding rods are packed, labeled with important information, and, in certain circumstances, certified to satisfy industry requirements. These disposable electrodes are delivered to welding supply stores and companies all over the world, where they serve as key components for connecting metals, assuring structural integrity and safety in a variety of applications.

Detailed Report Sample On Welding Rod Manufacturing

Market Potential Of Welding Rod Manufacturing

The worldwide welding electrodes market was valued at USD 3.02 billion in 2019 and is predicted to be valued at USD 3.79 billion by 2027, expanding at a 3.0% CAGR during the forecast period.

Because of rising demand for integrating diverse and non-metallic materials, the evolution of customized and unique shapes/designs, the introduction of new welding and cutting technologies, and many other causes, the welding industry is rapidly developing. Due to its ability to perform high precision welding in real-time, welding electrodes are increasingly being used in such situations. Furthermore, benefits such as compact size, adaptability, and low spark incidence are leading to increased deployment across a variety of industries, including automotive, building & construction, and others. The automobile sector, for example, is working hard to match its products with environmental norms and regulations, notably CO2 emissions. Welding electrodes improve welding skill, decrease waste, and boost overall output and efficiency.

Since engineers and welders doing welding activities on the factory floor have been taught on numerous welding precautions and discipline, but seldom on how to carry out these operations, the welding sector is presently experiencing challenges. Furthermore, rather than via apprentices or recognized welder training, welders and engineers generally learn to weld and execute their talents while performing welding operations. In this scenario, accidents are more likely to occur since the user is unaware of factors such as the time necessary to heat the metals, the supply of required current, and others.

Contents of Project Report

A project report helps you identify whether a project is worth pursuing. It presents the holistic view and brings complete insight of the business and its activity.

It acts as a guide for all the business operations, aids in taking all financial decisions related to the existing businesses and to the start-ups. It serves as roadmap to the business and provides information to the outsider who are wanting to know more about the business.

You will have the opportunity to build new goals and expansion ideas in one single document. Everyone, from the banks to potential investors, will need to have a look at the project report before they shell out any money.

A well drafted project report generally consists details about:

- Brief History of the Business

- The Promoters

- SWOT Analysis

- Industry Outlook

- Past Financial Statements

- Projected Financial Statements

- Infrastructure and Human Resource required

- CMA data

- Business model

- Requirement of Working Capital Funds

- Means of Finance

Other relevant information, if any.