Introduction

Feasibility Report For Aircraft Engine Manufacturers.

Aircraft engine manufacturing is a complex and crucial process that entails designing, producing, and assembling engines that power a variety of aircraft, including commercial jets, military jets, helicopters, and private planes. These engines are the heart of an aircraft, producing the thrust required to drive the aircraft into the air while also assuring the aircraft’s safe and efficient functioning. Extensive research and development precedes the production of aircraft engines.

Engineers and designers focus on developing new engine designs that include the most advanced technologies, materials, and manufacturing procedures to improve performance, fuel efficiency, and safety. Computer simulations, prototyping, and rigorous testing are used in this step to validate designs before they go into production.

The manufacturing process begins once the design is finished. To resist the harsh conditions and strains encountered during flight, it often requires precision engineering and the use of high-quality materials, sometimes exotic metals. Strict quality control methods are implemented during the manufacturing process to ensure that each engine fulfills stringent safety and performance standards.

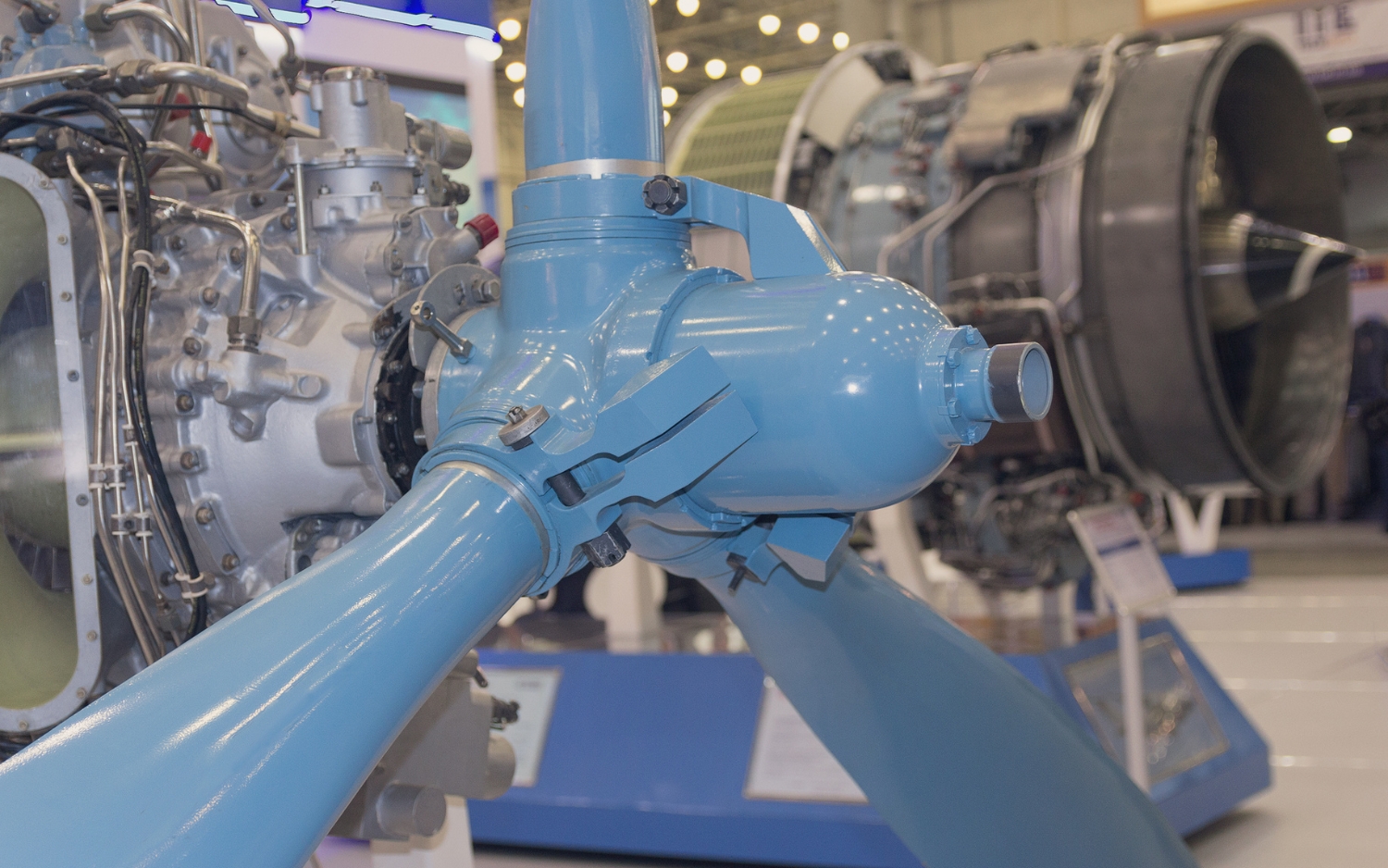

Aircraft engines are often constructed from hundreds or even thousands of different components that have been precisely designed and tested individually prior to assembly. To ensure accuracy and consistency, skilled specialists and sophisticated technology are used in this delicate procedure.

Feasibility Report Sample On Aircraft Engine Manufacturers

Market Strategy of Aircraft Engine Manufacturers

The global aircraft engine market was valued at USD 49.01 billion in 2021 and is expected to increase at a CAGR of 10.87% from USD 54.34 billion in 2022 to USD 137.54 billion by 2030.

The worldwide aviation engine market is expected to develop due to rising demand for more efficient and comfortable passenger and freight aeroplanes. Aircraft engines are likely to play a larger role in the military sector’s fight against drug trafficking, illegal infiltration, and terrorism, even if demand for commercial uses is higher. In the commercial sector, aircraft engines could be installed in newly manufactured commercial aircraft at an increasing rate to keep up with the increasing number of airline passengers.

The demand for aviation engines with greater fuel efficiency, small size, and lightweight is increasing. Due to rising demand for air travel, airlines have expanded their fleet of aircraft. As a result of the requirement for new aircraft, the market is expected to rise. Furthermore, the increased concern about reducing carbon emissions has diverted focus away from the development of new aviation engine types such as electric or hybrid engines, which are expected to boost the market growth.

The global aviation engine market is divided into three segments: end-user, technology, and region. The aircraft engine market is divided into two segments: commercial and military. The aviation engine market is divided into two types based on technology: conventional engines and electric/hybrid engines.

Aircraft engine manufacture is a high-stakes sector that requires constant innovation as well as strict adherence to rules and environmental requirements. Continuous research and development is driven by the desire for higher fuel efficiency, lower emissions, and quieter engines. As aviation technology progresses, aircraft engine manufacturers play a critical role in defining the future of air travel by providing engines for the next generation of aircraft.