Project Report For Oxygen Cylinder Filling plant

Introduction

Project report for Oxygen Cylinder Filling plant is as follows.

Depending on temperature and pressure, it can be a solid, liquid, or gas. In the environment, it exists as a diatomic gas. There is a covalent double connection between these two oxygen atoms. Oxygen atoms and gases are reactive molecules necessary for life on Earth.

It’s a blast. Inert gases are those that do not react with other elements. It is a colourless, tasteless, and odourless gas that makes up 21% of the atmosphere and is found in water, rocks, minerals, and many organic compounds.

Steel is the most significant commercial usage of oxygen gas. Hydrogen peroxide and nitric acid, for example, must be manufactured in massive amounts. It is also utilised in the production of antifreeze, polyester, and chloroethene, a PVC precursor.

Oxy-acetylene metal cutting and welding require oxygen. Sewage and industrial wastewater treatment is becoming more common. In industrial chemistry, this gas is used. It is used to make acids such as nitric acid and sulfuric acid. The most reactive is ozone O3. It is employed in a variety of chemical processes.

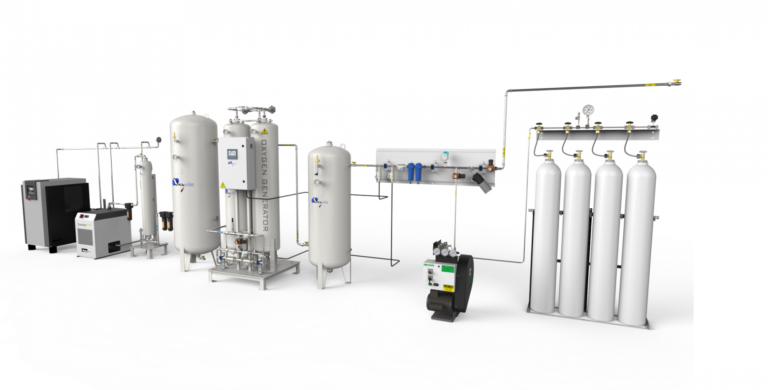

Process of Oxygen Cylinder Filling Plant

Production of Oxygen: The first stage is to create or get oxygen gas. Cryogenic distillation, pressure swing adsorption (PSA), and membrane separation are all ways for producing oxygen. These techniques remove oxygen from air, resulting in a pure oxygen stream for subsequent processing.

Oxygen Compression: Following the production of oxygen, it must be compressed to increase its pressure for storage and filling. Compressors are used to compress the oxygen gas to the required pressure, which is typically 1500 to 3000 pounds per square inch (PSI).

Filtration and Purification: The compressed oxygen gas is filtered and purified before being filled into the cylinders to remove contaminants and pollutants. Filters and molecular sieves are used to remove particles, moisture, and other impurities that could degrade the oxygen gas’s purity.

Cylinder Preparation: Empty cylinders, which are frequently made of steel or aluminium, must be inspected and prepped for filling. Inspecting the cylinders for damage or problems, checking correct valve performance, and cleaning the cylinders to remove any lingering pollutants are all part of this process.

Filling Procedure: The prepared cylinders are linked to the filling system, which comprises of high-pressure hoses, valves, and pressure gauges. Before starting the filling process, the operator ensures that the cylinder is correctly attached and secured. The compressed and filtered oxygen gas is then fed into the cylinder until it achieves the necessary fill pressure.

Pressure Testing: After the cylinders have been filled, they are pressure tested to guarantee their integrity and safety. This entails putting the cylinders to a hydrostatic pressure test, in which they are filled with water and pressurised to a level greater than their rated operating pressure. The cylinders are examined for leaks or deformations, and those that pass the pressure test are declared fit for use.

Market Potential Of Oxygen Cylinder Filling Plant

The global market for oxygen cylinders and filters was valued at $4.2 billion in 2021 and is expected to reach $6.7 billion by 2031, rising at a CAGR of 4.6% from 2022 to 2031.

Oxygen cylinders and oxygen concentrators are critical pieces of medical equipment for people suffering from lung cancer, COPD, and other respiratory ailments. Patients utilise oxygen cylinders till they run out of compressed oxygen gas. Some oxygen concentrators, on the other hand, are battery-powered devices that filter and produce medical-grade oxygen, giving the patient with a limitless supply. Furthermore, the need for oxygen delivery is likely to rise, which might propel the worldwide cylinders and concentrators business throughout the forecast period.

According to the WHO, chronic obstructive pulmonary disease (COPD) caused 3.23 million deaths in 2019, with about 80% occurring in poorer countries. The primary causes of this disease were identified as growing urbanisation, increased pollution, and exposure to hazardous industrial gases and particles.

COPD patients frequently require hospitalisations and supplementary oxygen to relieve symptoms, which has led to an increase in the use of medical oxygen cylinders in developing countries.

Project Report Sample On Oxygen Cylinder Filling Plant

Need Help?

Create 100% Bankable Project Report