Project Report For Paneer Manufacturing Plant

Introduction

Project Report For Paneer Manufacturing Plant is as Follows.

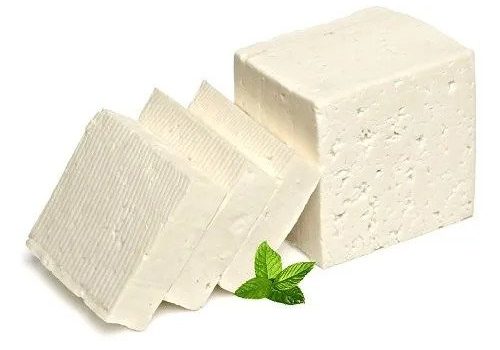

A paneer manufacturing factory is a facility dedicated to the manufacture of paneer, a famous milk-based Indian cheese. Paneer is a popular ingredient in Indian cuisine because of its soft, crumbly texture and mild, creamy flavour. The process of converting milk into paneer requires multiple processes. The first stage in the production of paneer is to get high-quality milk, particularly cow’s milk, which is heavy in fat and protein. The milk is collected and tested for quality to ensure it satisfies the required requirements. The milk is sent to the facility for additional processing after it has been authorised.

The milk is heated and pasteurised in the factory to destroy any hazardous bacteria and assure its safety for consumption. It is then chilled to a specified temperature before a coagulating ingredient, typically lemon juice or vinegar, is added. This coagulant induces curdling of the milk, dividing it into curds (solid) and whey (liquid). The curds are carefully gathered and placed to a muslin cloth-lined container or mould where the surplus whey is drained.

After that, the curds are pressed with a weight to eliminate any leftover whey and form the paneer into a firm block. The ultimate texture of the paneer is determined by the period of pressing. After achieving the correct texture, the paneer is withdrawn from the mould and can be sliced into various shapes or left as a block. After that, it is packed for distribution and sale. To lengthen the shelf life of paneer, certain production factories may use extra techniques such as cooling or freezing.

Types Of Paneer Manufacturing Plant

Small-Scale Manual Plants: These facilities are often run on a small scale and concentrate on traditional paneer production methods. They may include physical labour and artisanal methods like as curdling the milk with lemon juice or vinegar, moulding the paneer blocks by hand, and pressing them using traditional techniques.

Semi-Automated Plants: These plants have a moderate level of automation and mechanisation in their processes. They may include apparatus for pasteurising milk, separating curd, and pressing. Certain procedures, such as curd formation, cutting, and moulding of paneer blocks, may still need manual labour.

Large-Scale Completely Automated Facilities: These plants use modern technology and automation technologies to mass-produce paneer. They have automated milk handling, pasteurisation, curd creation, curd cutting, pressing, and paneer block shaping technologies. They may also include automated packaging solutions for more efficient and consistent packing.

Integrated Dairy Processing Plants: Some paneer production operations are part of integrated dairy processing plants that generate a variety of dairy products. These factories feature more equipment and procedures, such as milk receipt, milk processing, cream separation, cheese production, and packaging. They frequently have bigger manufacturing capacity and cater to a wide range of dairy products, including paneer.

Market Potential Of Paneer Manufacturing Plant

The paneer market size was 494 billion INR in 2022. The analyst projects that the market would grow at a 15.5% CAGR between 2022 and 2028 to reach INR 1,173 billion.

Different uses for paneer and the premiumization of its products are two elements influencing market growth. The market for paneer is expanding as a result of increased consumer demand for various paneer varieties, including masala paneer, spiced paneer, vegetable-impregnated paneer, filled paneer, paneer that is made with skim milk, paneer that is filled with protein, filled paneer, low-fat paneer that is filled with fibre, and paneer that is filled with masala. The need for vegetarian and plant-based protein substitutes has increased recently, and paneer, a dairy-based protein source, comes into this category. The demand for paneer may increase in the future as more customers look more wholesome, environmentally friendly dietary alternatives.

Also, the growth of the paneer business has been greatly aided by the Indian diaspora across the world. Particularly in areas with a sizable Indian population and rising interest in Indian cuisine, paneer has grown in popularity in international markets. The expansion of internet meal delivery services and the rising recognition of Indian restaurants throughout the globe have opened up prospects for paneer producers to serve the foodservice sector.

Project Report Sample On Paneer Manufacturing Plant

Need Help?

Create 100% Bankable Project Report