Project Report For Toothbrush Manufacturing

Introduction

Toothbrush Manufacturing project report is as follows.

A toothbrush is a tool for oral hygiene used to clean the teeth, gums, and tongue. It includes a handle that makes accessing the back of the mouth simpler and a head of closely spaced bristles that can be used to apply toothpaste.

The raw ingredients you need to start a toothbrush manufacturing company, which helps you produce toothbrushes like Nylon wire for producing bristles, and plastic for handles Packing materials include cardboard and plastic. start a toothbrush business The following kind of things are necessary for us, including Investment, Earth machine, Staff, Registration, and Licensing, as well as the necessity for Space, Electricity, and Staff.

You must first register your business as an MSME before you can start manufacturing toothbrushes. Obtain the Pollution Control Board’s NOC and the factory’s license for your production unit. You will also need to register for GST. If you want to market your products using your brand name, you must register your trademark; once you do, your business will run smoothly.

If you want to start a business making toothbrushes, you also need land, a warehouse, space for the machines to run, and an office. Additionally, you need two to three experts with sufficient experience in this subject; nevertheless, you can start by hiring just one. The machinery of the company will need a 5 or 8-kilowatt electrical connection. Making toothbrushes is a little business that can be started in a small room of your home, but it’s essential to have enough area for all the tasks to be carried out there. In actuality, you could launch this business from a 12- by 12-foot space in your house.

Project Report Sample On

Toothbrush Manufacturing

Get Completely Custom Bankable Project Report

Depending on your skills and the scale at which you want to establish your business, you can choose the location. Additionally, you have adequate space to expand production without running into any problems and may easily shift the plant from one site to another.

Toothbrush Manufacturing Process

Handle Molding: To make brushes, plastic is heated until it becomes liquid, then it is cooled by pouring it into molds, where it is given the required shape. The machine handles the entire process. So don’t let it cool down for too long. Following this, the machine also performs the task of covering the handle with rubber, which immediately improves the brush’s grip.

Filling Machine – In the first step, the task of applying the brush teeth (bristles) to clean the teeth is performed once the brush handle is fully prepared. The majority of the nylon used to make these brush bristles is automatically machined into the brush handle. Machines are far faster than humans at this task of attaching the bristles to the brush.

Trimming: This operation, now in its third stage, involves cutting the bristles into the right size and shape. Different brushes are prepared for cleaning in various ways through this process. The packaging of these toothbrushes is crucial since only products that are appealing to the eye are sold in the market. The toothbrushes are packed in transparent cardboard and plastic boxes throughout this procedure, and they are now entirely prepared for market shipment.

Market Potential Of Toothbrush Manufacturing

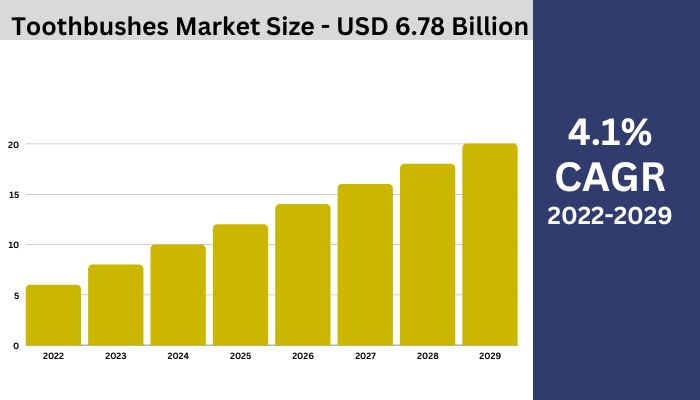

The market for toothbrushes was projected to be worth USD 6.78 billion in 2021. Between 2022 and 2029, the global market is projected to grow at a 4.1% CAGR, from USD 6.90 billion in 2022 to USD 9.14 billion in 2029.

India has a huge market potential for toothbrush manufacturing due to its large population of over 1.3 billion people, increasing awareness about oral hygiene and dental care, and rising disposable income of the middle class. The Indian toothbrush market is expected to grow at a CAGR of 6.3% during the period of 2021-2026.

The market size of toothbrush manufacturing in India is difficult to estimate accurately due to the presence of both organized and unorganized sectors. However, as per the data available, the toothbrush manufacturing industry in India is estimated to be around INR 5,000 crore ($675 million) in terms of revenue. This includes both manual and electric toothbrushes.

The organized sector in the toothbrush manufacturing industry is dominated by a few key players such as Colgate-Palmolive, Hindustan Unilever, and Dabur India. These players hold a significant market share and are constantly innovating to cater to the changing demands of consumers. They are also investing heavily in marketing and advertising to create brand awareness and increase their market share.

The unorganized sector, on the other hand, is made up of small and medium-sized enterprises (SMEs) that manufacture toothbrushes at a lower cost. These manufacturers cater to the lower end of the market and offer toothbrushes at a cheaper price point. However, they face stiff competition from the organized sector and struggle to compete on quality and innovation.

The Indian toothbrush market can be segmented into manual and electric toothbrushes. The manual toothbrush segment dominates the market due to its affordability and widespread availability. However, the electric toothbrush segment is expected to grow at a faster rate due to increasing awareness about oral hygiene and the benefits of using electric toothbrushes.

There are a number of factors that are driving the growth of the Indian toothbrush market. Firstly, there is increasing awareness about oral hygiene and dental care among the population, which is leading to a growing demand for toothbrushes. Secondly, the rising disposable income of the middle class is enabling people to spend more on personal care products, including toothbrushes.