Project Report For Non Woven Fabric

Introduction

Non Woven Fabric project report is as follows.

A “nonwoven fabric” is a substance that mimics cloth and is constructed of long and short staple fibers that have been mechanically, chemically, thermally, or solvent-bonded together. Non-woven fabrics have a structured internal structure.

Non-woven fabrics do not require weaving or knitting, in contrast to conventional materials like cotton, linen, wool, and silk. Felt is one of the most typical types of non-woven fabric. A dense textile is created by churning fibers in a solution until they interlock.

The way the fibers are joined together determines the type of non-woven fabric: mechanical bonding (fiber entanglement), chemical bonding (fibers are joined chemically with glue-like chemicals), or thermal bonding (where low-melt fibers are used and heat is used to melt the fiber to each other). Apart from being labelled as nonwoven, the resulting fabrics don’t share much in common. To adjust fabric qualities or reverse engineer fabrics depending on functional requirements, nonwoven components such as fiber selection, web formation, bonding, and finishing procedures can be changed.

Numerous sectors utilize non-woven materials extensively. Non-woven fabrics are used in the medical industry to make isolation gowns, surgical scrubs, and medical packaging. They are utilized as carpet backing in the carpeting business. Their qualities have also been extensively applied in the agriculture, building, and automobile industries.

Sample Project Report On Non

Woven Fabric

Get Completely Custom Bankable Project Report

Non-woven materials can have a look that resembles paper, felt, or woven fabrics. It may also have a flexible, soft hand or it may be stiff, harsh, or large with minimal pliability. And it might be many times thicker or just as thin as tissue paper. They could also be opaque or translucent. They may have very high tensile strength or low tear and burst strength depending on their porosity. They could be created through sewing, heat bonding, or glueing.

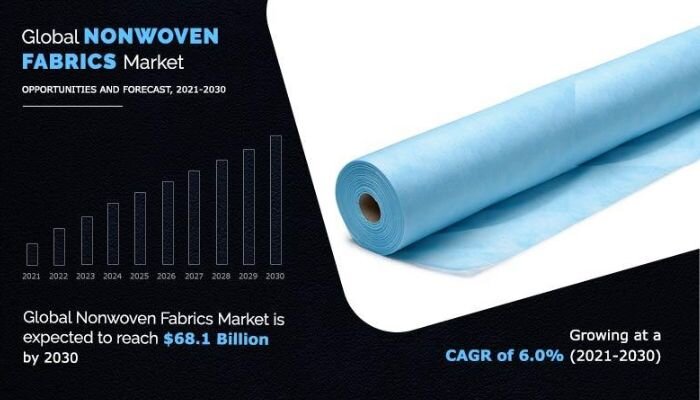

Market potential Of Non Woven Fabric

The market for nonwoven fabrics is expected to increase from its projected value of $38.3 billion in 2020 to $68.1 billion in 2030, at a compound annual growth rate (CAGR) of 6.0%.

Non-woven products are increasingly being used. Nonwovens have a wide range of applications and can be categorised as industrial materials, durable consumer items, and disposables. Due to its low cost and adaptability to a variety of demands, this form of item is becoming more and more popular in all these fields. While most disposable nonwovens are designed for single use, some, like dust cloths, can be washed and reused several times. In general, supplies for personal hygiene like diapers and sanitary napkins, medical items like surgical gowns and drapes, surgical and industrial masks, bandages, wipes, and towels, as well as bibs and even fancy dress costumes are used. There are numerous uses for durable nonwovens.

Consumer durables include both everyday items and home furnishings, like draperies, furniture upholstery, mattress padding, towels, tablecloths, blankets, and carpet backing, as well as household goods and clothing and apparel, like hats, linings, interlinings, and the reinforcement of other fabrics.

Filters, insulation, packing materials, roadbed stabilization sheeting or road-building materials geo-textiles, and roofing goods are just a few of the many industrial uses for these materials. Modern non-woven cloth first appeared in the early 1930s. A few textile businesses started experimenting with bonded polymers at that time as a means to use cotton waste. To create fabric straight from fibers, the first commercial manufacture of what are now known as non-woven started in the United States in 1942. The non-woven goods market has expanded significantly and has room to grow much more.